- New

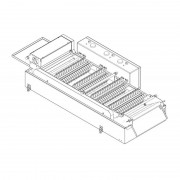

Modular Electric Compact Conveyor fryer 400/1100/12

Introducing a versatile modular fryer that can continuously fry a wide range of products with adjustable frying times from a few seconds to 50 minutes.

Description

This universal table fryer is perfect for HoReCa, street food enterprises, catering companies, and other enterprises in the catering sector. The fryer's continuous operation allows for easy frying of nuts, chips, chicken wings, chicken nuggets, pasties, pies, schnitzels, French fries, snacks, and more. The fryer's range of products can be easily expanded with additional modules.

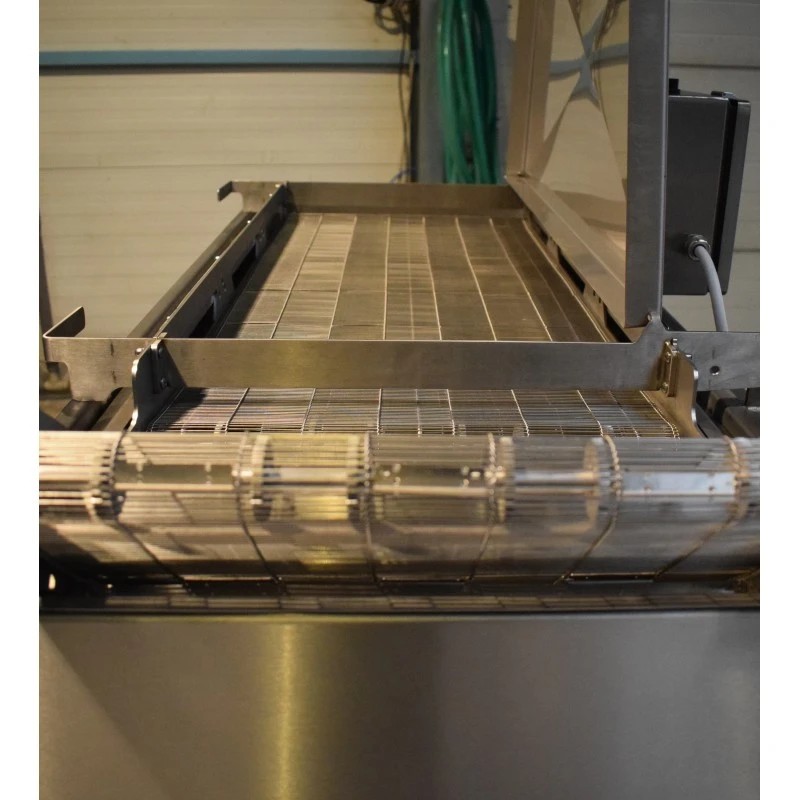

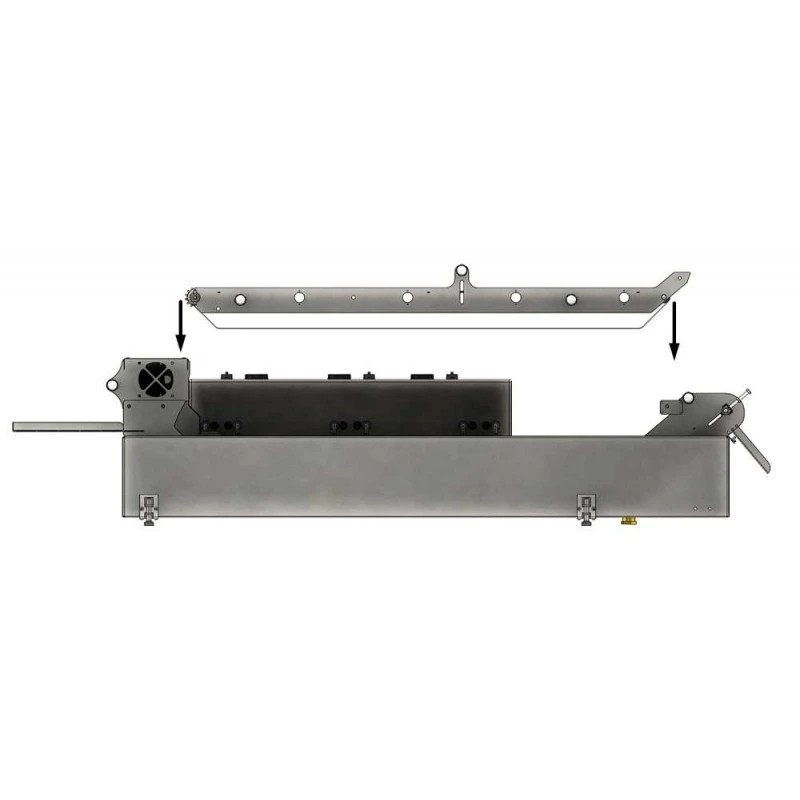

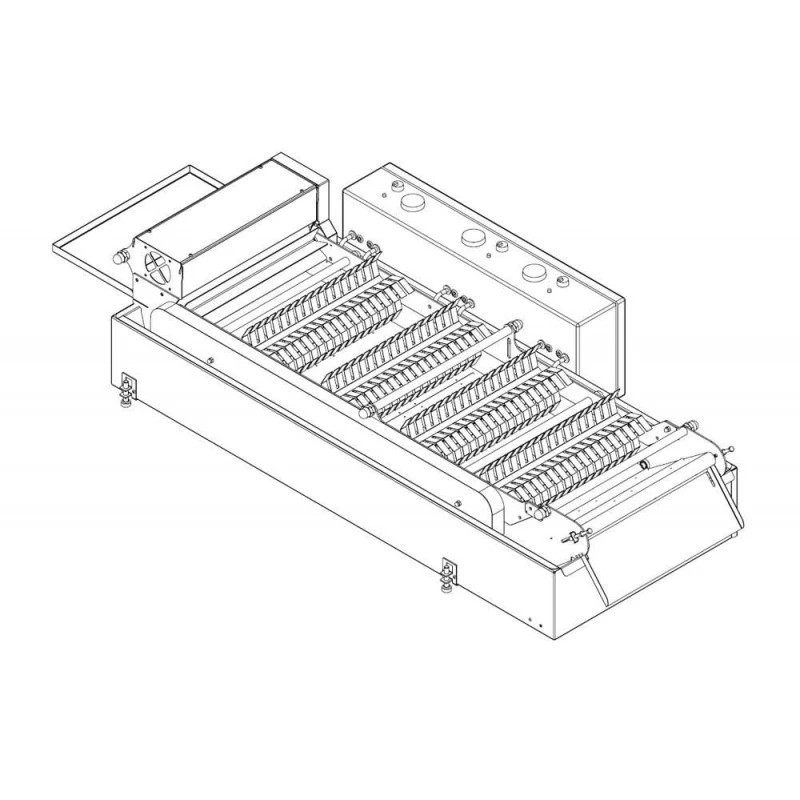

The compact tabletop fryer can provide continuous frying of food and is comparable in function and capability to professional industrial conveyor machines. Additional modules can be added for business diversification. The basic version of the fryer features a working bath made of food-grade stainless steel, a body with thermal insulation and an external decorative casing made of polished stainless steel. A working conveyor with a fine-mesh cloth made of steel recommended for use in the food industry is installed in the unit. The heating system is equipped with individual thermostats for each heating element, and the conveyor speed can be smoothly controlled with a wide setting range, from a few seconds to an hour. The control system is installed directly on the body of the working bath, making it easy to adjust the operating parameters. The electrical panel with heating elements can be quickly and easily cleaned using a system of brackets and connectors.

A "cold zone" is located under the working area, which helps slow down the process of oil deterioration, carbonization, and increases its service life. The walls of the case are equipped with 15 mm thermal insulation with a heat-reflecting effect. The fryer is equipped with a needle valve located at the lowest hydraulic point of the working area, which allows you to smoothly adjust the flow of drained oil and completely empty the working bath from oil. A perforated loading tray is located in the entrance area, which helps remove excess breading/liaison and small particles that have separated from the product.

The product is loaded onto the working conveyor of the fryer and is immersed under the working oil level, moves along it at a given speed, and is taken out for unloading, which ensures uniform frying of the product without damage, with the same quality of the degree of frying of each batch.

The basic equipment with a stainless steel conveyor can be used to fry nuts and other similar products with low water content, which do not float to the surface during the frying process. The fryer can fry large volumes of various convenience foods, making it suitable for professional hotel kitchens, small food enterprises, and the production of nut butters.

Additional modules can be purchased to expand the range of products, making it easy to switch from roasting one type of product to another. The fryer can also be used as a conveyor blancher when changing oil to water.

The fryer features stainless steel heating elements with direct powerful heating, fast and highly efficient heating to reduce oil carbonation in the heating sections, individual thermoregulation of each heating section, safety thermostats on each heating element, simple and convenient maintenance, and a compact installation that can be placed on worktops/surfaces in professional kitchens. The fryer also features thermal insulation of the working bath, a guaranteed 100% oil discharge, controls located directly on the body of the fryer, an immersion thermometer for monitoring the current oil temperature, a maximum heating temperature of up to 200 degrees C, low oil volume due to reduced working bath depth, a work surface for pre-layout of the product, a feed tray with a perforated section to dispose of excess crumbs/liaison before loading into the fryer, a modular fryer system with a large number of additional equipment for different products and accessories.

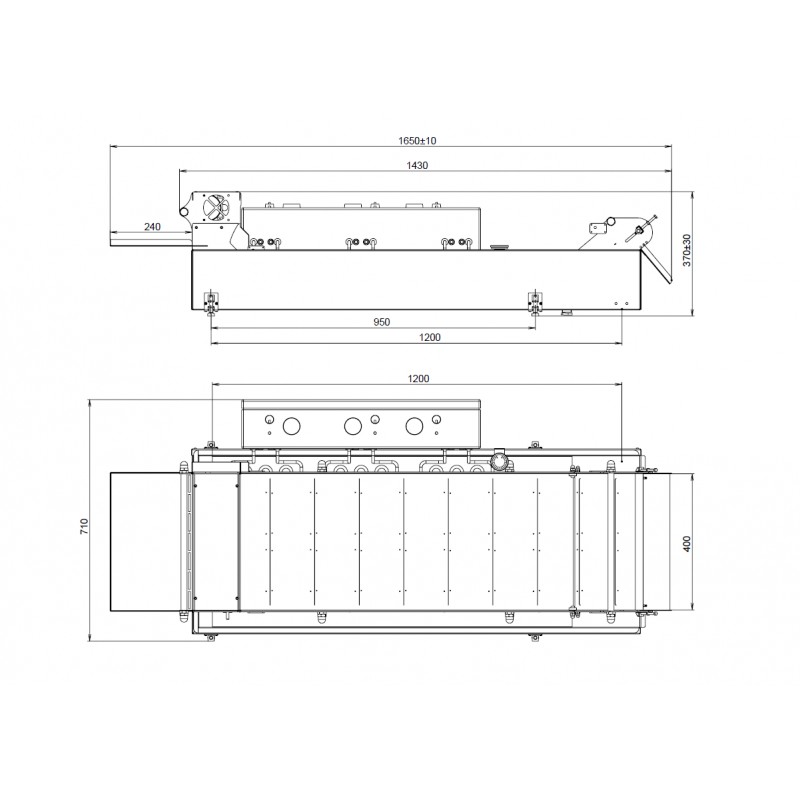

Technical data:

- Power supply: 3-phase, 380V, 50Hz.

- Installed power - 8 kW.

- Capacity - up to 25 kg/hour.

- Dimensions: 940 x 730 x 560 mm.

- Working temperature range - from 20 to 200°C.

- Weight - 75 kg.

Maintenance

The fryer requires regular maintenance to ensure its proper functioning and longevity. Cleaning of the unit should be carried out regularly, in accordance with the manufacturer's recommendations. It is important to regularly check the heating elements and thermostats, as well as to replace the oil in a timely manner. In addition, the fryer should be inspected for any signs of wear and tear, and any damaged parts should be replaced as soon as possible.

The versatile modular fryer described above is an excellent choice for HoReCa, street food enterprises, catering companies, and other enterprises in the catering sector. Its ability to fry a wide range of products with adjustable frying times makes it a versatile and cost-effective solution for businesses of all sizes. With its compact size and modular design, it is easy to install and maintain, and it can be expanded with additional modules to meet the needs of any business. Whether you're frying nuts, chicken wings, or French fries, this fryer is a reliable and efficient choice for any kitchen.

251 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

- New

- New

- New

Continuous multi-zone automatic tempering machine TurboNormix 250

- New

- New

- New

- New

- New

- New

Modular perforated polypropylene shelves for cheese racks / shelves

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT