- New

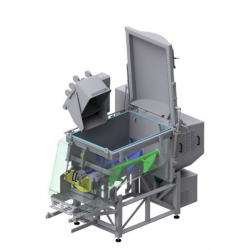

Brine Mixer GH 107

Our mixers are specifically designed to handle a large number of ingredients while efficiently dissolving dry ingredients into the brine, working with the most viscous types of brine.

Description

Over time, the brine and marinade recipes have been modified to include more ingredients/dry substances. This has radically sharpened preparation requirements as regards handling, mixing and dissolving the ingredients. Whether you are injecting hams, bellies, loins or whole birds, you are likely incorporating more solids than ever before into your brines.

The tanks are double jacketed and insulated and can be equipped with a cooling functionality. The cooling liquid circulates between the walls, round the entire tank so it is evenly distributed around the whole surface in order to achieve uniform cooling. The cooling jacket allows for storage of brine and the usage of cooled brine has several functional benefits; it helps maintain a cool temperature in the meat, aids the protein binding capacity of the meat, and contributes to a longer shelf life of the product by reducing bacterial growth!

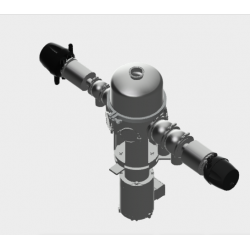

• A powerful centrifugal pump guarantees full vacuum effect in the venturi valve, even with viscous brine.

• The infeed hopper is equipped with a vibration motor to feed in/down the ingredients/dry substances makes the work easier and even possible if the brine/marinade is viscous.

• Effective and powerful agitator with large capacity combined with low rotation speed to prevent foaming.

• Digital thermometer that also regulates set temperature.

• External, automatic level switches for continual transport of brine to external container.

• Inner tank and hopper made of acid-resistant stainless steel.

• Tapered bottom – 100% of the brine is utilised.

• Pneumatic valve with automatic shut-off after brine transport to prevent trickles.

• Level switch prevents the pump from running dry.

• Cooling jacket covers the entire surface area of the tank for maximum cooling.

• Cooling jacket and bottom have 50-mm insulated walls.

• Additional storage tanks can be connected without requiring extra transport pumps.

• Option for full automatization – including recipe control.

184 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

Continuous drum coating machine for adding spices and flavors AD

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT