- New

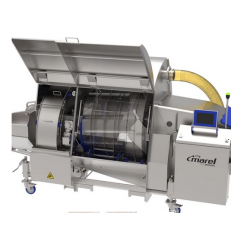

Breading and battering machines

Breading and battering is a preliminary treatment of foods, providing a special coating around them before they are then subjected to heat.

In the food industry, this is done to improve the visual appearance and taste of various foods by providing a crunchy exterior, as well as to extend products’ shelf life. Breading consists of products that have been ground or a mixture of ingredients that act as a protective layer, preventing moisture from evaporating and maintaining the shape of semi-finished products. Thus, the food stays juicy after cooking and it is given new flavor notes.

On an industrial scale, it was breadcrumbs that were first used for breading, mainly in the making of semi-finished seafood products.

Over time, the range of breaded products has expanded significantly. Various forms of breading are applied to improve products’ visual appearance and texture and to seal in flavor and juiciness.

Modern breading and battering equipment allows you to apply breading to a wide variety of food products, from crunchy fish products to snacks.

The function of breading and battering machines is to apply various breading and battering ingredients to:

- meat (schnitzel, rump steak, chops);

- fish (whole fillets and pieces);

- seafood (shrimp, calamari);

- poultry (wings, chicken legs, fillets);

- vegetables (zucchini, cauliflower).

The products that will be breaded can come in either fresh or frozen form.

This equipment is used not only for whole products (e.g. pieces of meat or poultry) but also when making various molded products:

- meat patties,

- meatballs,

- meatloaf,

- nuggets,

- cheese-based foods.

Breaded and battered products are highly in demand in the market, in spite of the growing popularity of foods that have lower fat and carb content.

Advantages of breading and battering:

- nutritional value is increased;

- the visual appearance and taste is improved;

- the flavor is altered for the better;

- the products’ texture changes.

Breading and battering equipment is designed to automate the process of dry sprinkling and glazing semi-finished products with a layer of liquid. This equipment provides products with an intensive and even coating so that they can then be frozen or immediately fried.

Synonyms: breading machines, breading and batter equipment, chicken breading machine, automatic breading machine, food battering machine, food battering equipment, universal breading and battering machine.

Equipment for different kinds of breading and battering.

One thing to understand about breading and battering equipment in the food industry is that all the products and ingredients used, as a rule, appear in a wide and complex range of combinations. Within your food-production process, you should carefully consider which equipment to use and how pieces of equipment interact with one another.

There are two kinds of breading and battering processes: dry and liquid.

The breading and battering process consists of the following:

- preliminary sprinkling,

- application of liquid batter,

- coating with dry breading.

Various combinations of these processes are employed in the making of different products. The production of some products may involve the step-by-step application of all three coating processes. For other products, two operations will be enough or processes will need to be repeated (multilayer breading).

|

Type of breading and battering |

Ingredients in breading mixture |

Product |

|

Dry |

Dry breading (ground dry white or wholegrain bread). |

Fish and meat patties, schnitzels, meatballs, meatloaf, as well as carrot- and cabbage-based patties, cauliflower, and cheese sticks. |

|

Flour (wheat, corn, rice, buckwheat, oat, or rye). |

Patties made from minced meat or fish, meatballs, fish sticks, fish fillets. |

|

|

Ground cereal flakes (buckwheat, oat, or rice). |

Semi-finished products from meat and fish: fillets, patties, chopped steaks, meatloaf. |

|

|

Potato starch. |

Natural patties, chicken fillets, chops. |

|

|

Semolina. |

Products based on fish, meat, or vegetables, poultry, seafood, cauliflower. |

|

|

Hard cheeses (or alternately a cheese and flour, starch, or breadcrumb mix). |

Meat, minced meat products, fish fillets, vegetables, seafood. |

|

|

Chopped nuts. |

Fish fillets, meat, vegetables. |

|

|

Crumbled crackers or chips. |

Semi-finished products from minced meat or fish, cheese bites, crab sticks. |

|

|

Chips made from potato, carrot, pumpkin, or zucchini |

Meatballs, minced-meat rolls. |

|

|

Liquid |

Beaten egg (alternatively egg white or yolk beaten separately) |

Semi-finished products from meat and fish, vegetables |

|

Liquid dough (batter) |

Vegetable sticks, onion rings, shrimp, cheese bites, cauliflower, fish fillets, various fast-food. |

|

|

Mix of various ingredients: flour, starch, egg, milk, spices, baking powder, and stabilizers. |

Meat patties, meatballs, meatloaf. |

|

|

Marinade |

Steak, rib-eye, porterhouse. |

Among the numerous coatings for potato, vegetable, meat, and fish products, as well as coatings for snacks and pastries, the following are available:

- gluten-free,

- egg-free,

- with or without seasonings.

The breading and battering process can also change the nutritional value of the product, for example, by including vitamins in the breading mixture.

Breading stages

A feature of breading equipment’s design is the presence of two sections for dry and liquid breading, respectively.

Within production, different methods of applying breading are used.

The process can involve one or multiple layers of coating depending on:

- the input;

- the required amount;

- the quality of the final coated state.

Each pass necessarily involves a stage of applying wet and dry breading. Often, before the wet layer is applied, a preliminary layer of powder is applied to the raw input.

Preliminary sprinkling

With the help of a preliminary sprinkling step, you can significantly increase the adhesion of liquid batter, reliably seal in the moisture in the product, and provide a dry, rough surface for high-quality application of breading.

As an initial sprinkling, ground breadcrumbs or special flour are used. This sprinkled powder may be an off-the-shelf product or specially formulated for a specific product or process.

The aim of the first layer is to provide a suitable surface for the application of subsequent layers.

What preliminary sprinkling does:

- creates an adhesive layer to which the liquid batter will be applied;

- thickens the layer and reduces losses from lost air;

- preserves the taste of the input, e.g. as it is fried;

- seals in the moisture within the product.

For applying breadcrumbs to whole-muscle and piecewise products, a breading drum is used. Inside the breading drum, the portioned pieces are dropped into a special mixture and shaken. This method is used when breading piecewise products such as natural patties, steaks, schnitzels, and chops.

The second way of applying the coating, sprinkling, is mainly used for molded products, since in this case the products do not collide with each other and so would not be damaged (cutlets, meatballs, meatloaf).

The final step is to remove any excess amount of this preliminary coating that might cause problems when the wet coating is subsequently applied. This is done by blowing the product with air or shaking it.

Products that are given a preliminary layer will have a better coating overall.

Liquid batter

Adhesive batter is a liquid medium that serves as a "glue" to improve the dry breading’s adhesion to the product. The stickiness is very important and the viscosity of a given mixture must be carefully controlled in order to ensure that enough dry breading will adhere to the product.

The batter is applied by dipping the product. Products enter a special device where they move on a conveyor through a tank that contains the liquid batter. The product is submerged in the batter so that the liquid completely covers it.

Another way of applying batter, cascading, is used with batters that have a low or medium viscosity. A batter that is relatively low-viscosity is fed from above onto the product, and what does not hit the product is then recycled. An additional pass of the product through a small accumulation of batter serves to ensure full coating.

Liquid batter comes into types: leavened or unleavened. Which one to choose depends on your products’ formulation.

To improve products’ taste and appearance, flavorings and food colorings are sometimes added to liquid batter.

Dry breading

In devices that perform dry processing, the product is moved along a special tray with a layer of breading material, and thus the underside of the semi-finished product is coated. The product moistened with batter falls under a continuous stream of loose particles that cover the top of the product.

The composition of the dry breading can vary depending on the desired flavor, texture, and visual appearance of the final product.

The thickness of the layer of breading depends on the viscosity of the breading itself. The thicker the breading, the thicker the layer that will be created around the product.

The design of the conveyor includes pressure rollers that press the breading onto the product, and thus the breadcrumbs will stick to the layer of batter. This ensures that a thicker layer of breading is applied.

Excess breading that does not adhere to the product is blown off using blowers (fans) in order to avoid bringing that excess breading to the frying process.

Features of breading and battering machines

The machine for applying liquid batter and dry breading is a double-sided belt conveyor that performs multiple operations on products sequentially: automatic glazing with batter and then sprinkling with breading ingredients.

The conveyor belt, which ensures uniform distribution of the coatings, comes in different widths and the speed at which it moves can be adjusted.

The operator places the semi-finished product on the conveyor, where the product is immersed in the batter and then is fed into a tank with the dry mix.

If a preliminary sprinkling step is provided, the product is sprinkled with dry ingredients before it is immersed in the liquid medium.

For a liquid medium, the batter is poured and the product is immersed in it, after which the excess liquid batter is removed before the product is sent on to the next stage of processing. Baths for liquid media vary in their volume. The baskets containing the dry breading ingredients also come in different sizes.

A production line can include a machine for whipping batter for e.g. fish, onion rings, shrimp, or battered cheese.

The process of breading with a dry medium consists of immersing the product in the breading material at the bottom and simultaneously cascading breading down onto it. The operator can set the depth of immersion and the thickness of the mixture coming from above, as well as the speed of the conveyor belt.

Breading equipment comes in tabletop and floor forms. What equipment to choose generally depends on your production process. For example, if you are preparing breaded meat patties, your production line can be supplemented with a molding machine.

Breading equipment represents an important link in the making of a variety of semi-finished products, and it boosts your output and the quality of your products.

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT