Coating and enrobing machines

Coating and enrobing machines are equipment that serves to coat, enrobe, or impregnate medications or food products with a hard shell or with a solution. These are generally products that have a round shape and are all of approximately the same size: nuts, candies, seeds, and candied fruits. It is often necessary to create a beautiful glossy shell when making these products, in order to improve the visual appearance and taste of the result. That is, these machines solve the problem of how to make nuts and dried fruit more savory, and cookies and gingerbread more visually appealing.

The coating is applied by either enrobing the product or by impregnating porous material. Thanks to coating and enrobing machines, the process of applying coatings is fast, high-quality, less time-consuming for personnel, and effective.

Synonyms: food coating machine, enrober, food glazing machine, food coating cauldron, enrobing/coating drum, food glazing equipment.

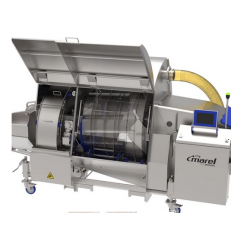

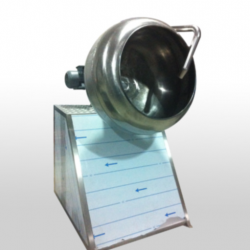

A coating machine usually takes the form of a large coating cauldron or a coating drum mounted on a fixed frame, which rotates using a special mechanism (a gearbox). The drum can operate continuously or with pauses in order to discharge the ready product.

The way that a coating machine works might be as follows: the product that is to be coated (nuts, candied or dry fruits, seeds, candies, gingerbread, cookies) is loaded through the opening of the coating drum. In a different section of the drum, the liquid composition that will be used for coating is loaded (depending on the technology, this might be syrup, chocolate, or fondant) and a powder (again, depending on the technology, and it could be e.g. powdered sugar, cocoa, or crushed nuts). The drum rotates and the liquid and powder enrobe the product as it rolls over the drum.

To start and end the process of coating foodstuffs or medicines, and for loading and unloading the final products, the kettle is tilted manually or automatically by the operator overseeing the process.

The speed at which the drum rotates and the coating process itself can be adjusted depending on the specific product and the viscosity of the coating.

Glazing machines work in a somewhat different way. Semi-finished products (candies, gingerbread, ice cream, small cakes, waffles, curd, marshmallow, dried fruits) are fed via a conveyor belt into the glazing bath, where the freely-flowing glazing solution (sugar syrup, melted chocolate) enters. By means of a pump and special dampers, the evenness of the jet can be regulated, as well as the frequency or continuous supply of coating solution. After the glaze has been applied, the fan built into the plant blows any excess glaze off the product, and special smoothing rollers make the bottom surface of the product level, and it then enters the cooling tunnel.

Glaze can be applied onto the product:

- only on top

- only on the bottom

- on all sides besides the bottom

- all around

- with further decorative patterns (herringbone, waves, ladder, zigzag), which requires additional decorator elements that can be switched.

All of the elements of the coating and glazing machines which come into contact with the product are made from high-quality, food-grade stainless steel or brass, in order to avoid any undesirable contact or chemical effects on the food products or pharmaceuticals. Moreover, stainless steel is practical and easy to maintain, and it can be quickly cleaned after use.

The drum of the coating machine consists of several sections. The inner surface of the drum can be corrugated or with special blades, or it can have bent profiles for the movement of the product. When semi-finished products (cookies, candies, peanuts, seeds, dried or candied fruits) are loaded into the drum, in the first section e.g. syrup is supplied, and in the second section drying is performed with a stream of air and if necessary an oily/chocolatey mixture is added. Finally, in the last section the ready product is covered with a special talc that prevents the individual items from sticking to each other.

For certain products, additional modules are required. For example, glazing corn puffs requires a special pump with nozzles to supply oil. And in some cases a crusher can be added, and then ordinary sugar can be added to the drum instead of powdered sugar, as the sugar will be crushed already during the glazing process. Most often this is employed in the production of e.g. nuts (hazelnuts, peanuts) and fruits (for example, cranberries) covered in powdered sugar. This method can be used to produce candies or cookies sprinkled with nuts and waffle. The coating machine can be optionally equipped with a special drive to smoothly adjust the speed of movement, with a heating system and temperature control, with switchable coating drums of various sizes, and with other additional devices.

Coating and enrobing machines are used in the food, pharmaceutical, and agricultural industries. They can be used to cover nuts, candies, seeds, coffee beans, corn, gingerbread, dried or candied fruits, marshmallow, and round cookies with a glazed coating.

As the coating, one can use liquids that will subsequently harden or small, fine-grained ingredients. Generally, food products are covered in sugar, chocolate, cream, fruit mix, or sprinkled with cocoa powder, crushed nuts, or powdered sugar.

In pharmaceuticals, coating machines serve to create the outer coating for pills and vitamins. Coating helps to mask or improve the taste of medications, which is especially important for children’s medications, and it can also be used to adjust the speed at which medications are absorbed by the body.

In agriculture, coating machines can impregnate seeds with chemicals and cover them with a protective coating.

The process of coating and glazing is often used:

- to give the final product an attractive appearance

- to obtain new taste qualities

- to mask unpleasant tastes (in the case of medications)

- to make all products the same size

- to obtain various textures, colors, and and shapes for the end product

The final product is obtained as the coating material (sugar solution, chocolate, cream, oil, fruit mix) is gradually supplied while the raw ingredients (nuts, seeds, tablets, candied fruits, dried fruits) are gradually and continually mixed.

Processes that occur as the machine operates.

Coating technology includes giving pieces of product the shape shape and subsequently covering the product with a coating. The uniformness of the coating is ensured by supplying the liquid ingredient with a special dosing pump and blowing the product with compressed air.

The coating process takes no more than 5–6 minutes on average. After this, the ready product is discharged from the drum and packaged into bags or boxes to be transported further.

As a result of this processing in the coating machine, small homogeneous products take on an attractive visual appearance and made convenient for further transportation and use.

Types of coating and enrobing machines

Coating and enrobing plants are categorized depending on whether the coating process runs continuously or not, on the size of the coating drum, and on the method used to apply the coating.

The coating process can run either continuously or in batch mode.

When the process runs in batch mode, the product is fed into the coating plant, goes through the entire coating process, and then is removed from the drum. After this, the next portion of raw inputs is poured into the coating drum and the process starts all over again.

When a plant runs in continuous mode, the coating process never stops. The ingredients are fed into the respective section of the coating drum and pass through all stages of processing. Tunnel coating machines, for example, run in a continuous mode.

The volume of the coating drum can range from 1 to 4.5 square meters. The volume of the coating drum depends on the method used to apply the coating and whether the process runs in continuous or batch mode.

The method used to apply the coating can be:

- enrobing (coating properly speaking)

- vacuum impregnation (vacuum diffusion). More details can be found here

- glazing

- sprinkling (breading). More details can be found here.

|

Processing method |

What the process entails |

Initial product |

Final product |

|

enrobing (coating properly speaking)

|

the process by which a uniform coating is applied to raw inputs, which had been preliminarily given a uniform shape |

nuts, seeds, candied fruits, dried fruits, cookies, gingerbread, candies, vitamins and supplements |

granulated seeds; sugar- or chocolate-covered nuts; salted nuts; candies in a sugary coating; candies, cookies, gingerbread covered in chocolate or a fruit or cream coating; dried and candied fruits covered in sugar or chocolate; supplements in a coating. |

|

glazing |

the application of a uniform coating to initial inputs of different sizes. The glazing can be applied either on one side (atop), on multiple sides (the top and sides of the product), or all around. |

corn and rice grains gingerbread, cookies, cottage cheese, marshmallows, waffles, ice cream, cake. |

glazed corn puffs and rice puffs, glazed gingerbread, chocolate-covered marshmallows, chocolate-covered waffles, ice cream with a coating

|

|

sprinkling |

covering the input product with a dry ingredient; in preparation, the product is first coated with a sticky solution.

|

nuts, candied fruits, dried fruits, cookies, gingerbread, candies |

sugar-coated nuts, salted nuts, candies sprinkled with nuts or a waffle coating; candies, cookies, and gingerbread sprinkled with sugar; sugar-coated dried fruits and candied fruits |

Vacuum impregnation of the product is done in a periodic mode. More details can be found here: Sprinkling and glazing – continuous mode. Enrobing (coating) can be performed in either mode, continuous or periodic. This depends on your inputs, the coating, and the final result that you require.

Coating machines can be used both in large enterprises and in small businesses that produce food products, confectionery, vitamins, and agricultural products.

List of initial inputs and final products.

|

Initial input |

Final product |

|

Nuts: peanuts, hazelnuts, almonds |

Nuts coated in sugar, chocolate, cocoa, cream, or salt |

|

Seeds: pumpkin, sunflower |

Seeds coated in chocolate or salt |

|

Grains: corn, rice, coffee |

Glazed rice puffs and corn puffs, chocolate-covered coffee beans |

|

Confectionery: candies, gingerbread, cookies, marshmallows, waffles, cottage cheese |

Candies, cookies, and gingerbread in chocolate, cocoa, cream, fruit mix, glazed curd snacks, chocolate-covered marshmallows |

|

Dried fruits and candied fruits: cherries, cranberries, prunes |

Chocolate- and sugar-covered dried fruits and candied fruits |

|

Seeds: any medium–large seeds – wheat, rye, cucumber, squash, radish, etc. |

Plant seeds chemically treated and granulated for better storage and easier planting |

|

Medications: tablets and pills with an unpleasant taste |

Children’s vitamins and medications |

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT