- New

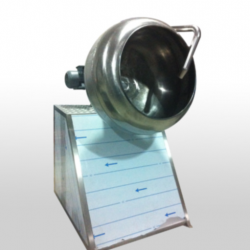

WOLF Belt-Coating Cabin

Our dragee machines of the type DRA have established themselves worldwide in a very short time and stand for sophisticated technology, quality and durability.

Description

Belt Coater WOLF Type DRA

DRA-600 with approx. 60 litres production volume

DRA-1200 with approx. 240 litres production volume

DRA-1600 with approx. 330 litres production volume

DRA-2000 with approx. 650 litres production volume

Our dragee machines of the type DRA have established themselves worldwide in a very short time and stand for sophisticated technology, quality and durability. Constant new requirements and tests in our laboratory with a wide variety of inserts and grease masses have driven the development of the machine and made WOLF the market leader.

By using a PLC control system, the machine can be controlled fully automatically in conjunction with the options (especially with weighing cells) and allows little time to be spent by operating personnel. A programmable recipe control simplifies operation and ensures consistent quality of the end product.

Various options allow the machine to be adapted to different requirements of the coating process. For example, light products such as extrudates and flakes can be processed by using spray nozzles. The process control also allows a combination with the nozzle pipe in order to be able to switch between the application systems during production.

When using a second nozzle pipe, the article can be coated with two different masses or a quick mass change can be made. A belt scraper system at the rear of the machine ensures cleaning from the belt, with the product residues being collected in a drawer under the machine.

Optionally, a heated scraper can also be installed in the production area. This allows the layer thickness of the chocolate mass on the belt to be reduced. The built-in heating liquefies the stripped material again and it drips back into the production process. This eliminates the need for a cleaning cycle after each batch and saves time and coating mass.

The performance of the machine depends on several factors. You have the opportunity to carry out trials in our laboratory with your own inserts and fat masses and gain experience. The laboratory costs will be charged when ordering a new machine within three months.

Currently, 4 types of dragee cabinets with different filling volumes are available. Of course, the output per hour depends on the desired end product and the raw materials used.

We will be happy to provide you with further details upon receipt of your enquiry, or we can determine this through a test in our laboratory.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT