Spices, herbs and seasonings

Spices and seasonings are both used to add flavor to food, but there is a difference between them.

Spices are dried parts of plants, such as seeds, bark, roots, or fruits. Examples of spices include cinnamon, cloves, and black pepper. They are often used to add distinctive flavors to food and are typically used in small quantities.

Seasonings, on the other hand, are a mixture of spices and other ingredients, such as salt, sugar, and herbs. They are often used to enhance the flavour of food and can be used in larger quantities than individual spices. Examples of seasonings include chilli powder, garlic powder, and Italian seasoning.

In summary, spices are individual ingredients used to add flavour, while seasonings are a mixture of spices and other ingredients used to enhance the flavour of food.

In the food industry, herbs are plant leaves that are used to add flavour to food. They are often used fresh or dried, and can be used in a variety of dishes, including soups, stews, sauces, marinades, and salads. Common herbs used in cooking include basil, parsley, thyme, rosemary, and cilantro. Like spices, herbs are used to add flavour to food, but they are typically milder in flavour than spices and are used in larger quantities.

The processing of spices, herbs, and seasonings can vary depending on the specific type of product, but here is a general overview of the process:

Cleaning and sorting: The raw materials are first cleaned and sorted to remove any foreign materials such as stones, dirt, or debris.

Grinding or milling: The cleaned spices, herbs, and seasonings are then ground or milled to the desired particle size. This can be done using a variety of equipment, including hammer mills, roller mills, and pin mills.

Blending: Different spices, herbs, and seasonings may be blended together to create a desired flavor profile. This can be done manually or using specialized blending equipment.

Sterilization: Some spices may need to be sterilized to remove any microorganisms or bacteria that may be present. This can be done using steam or dry heat.

Packaging: The final step is to package the processed spices, herbs, and seasonings for distribution. This can be done using a variety of packaging equipment, including pouch fillers, jar fillers, and bagging machines.

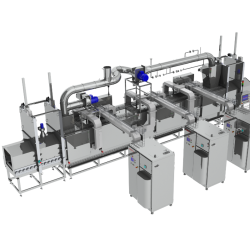

In terms of specific equipment used in the production of spices, herbs, and seasonings, some examples include:

Cleaning and sorting equipment: Air classifiers, destoners, gravity separators, and vibratory screens.

Grinding or milling equipment: Hammer mills, roller mills, pin mills, and ball mills.

Blending equipment: Ribbon blenders, paddle mixers, and fluidized bed mixers.

Sterilization equipment: Autoclaves and dry heat sterilizers.

Packaging equipment: Pouch fillers, jar fillers, bagging machines, and cartoners.

Of course, the specific equipment needed will depend on the type and scale of the production.

The most popular seasonings can vary by region and cuisine, but here is the list of some commonly used seasonings:

- Salt

- Black pepper

- Garlic powder

- Onion powder

- Cumin

- Paprika

- Chili powder

- Oregano

- Thyme

- Basil

- Rosemary

- Bay leaves

- Curry powder

- Ginger

- Turmeric

Of course, there are many more seasonings that are used in different types of cuisine, but these are some of the most commonly used ones.

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT