- New

Detectors

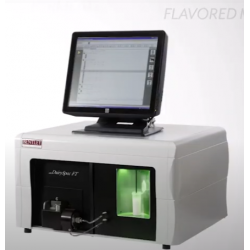

Detectors and quality-control inspection machines are absolutely necessary in fields such as the meat, dairy and other similar segments of the food industry. They are designed to thoroughly analyze products and containers, and reject the ones that do not meet the required quality standard. They allow you to determine the chemical makeup of raw ingredients, check for the presence of fungi, impurities, toxins, fecal components, metals, nitrates, etc. They are also used when working with herbs, berries, vegetables, fruits, cereals, milk, meat, tea, coffee, flour, spices, and chocolate. There are also devices intended for detecting defective glass bottles, PET bottles, or beverage cans.

Detectors & Inspection machines

Loss Prevention System Supersmart Scan & Go

Our news

2024-02-12

Herbs, seasonings, and spices have been integral to culinary arts for centuries, contributing unique flavours and aromas to dishes around the world.

2023-11-28

In the ever-evolving landscape of food processing, the role of industrial mixers is pivotal. These machines have revolutionized how ingredients are combined, presenting a transformative impact on both the food industry and the HORECA sector.

2023-11-06

Veganism is becoming increasingly popular, and as a result, there is a growing demand for vegan products.

2023-08-01

Pasteurization, named after the renowned scientist Louis Pasteur, is a critical process widely used in the food industry to ensure the safety and quality of various products.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT