French fries, nuggets, fish&chips

French fries and nuggets as well as fish&chips are among the most popular snacks.

The production and processing of such snacks may vary depending on the type of snack. The following are the general steps for the production and preparation of some types of snacks:

Here are the basic steps for French fries production:

Peeling potatoes. Potatoes are thoroughly washed and cleaned of earth and other contaminants.

Slicing potatoes. Potatoes are cut into strips using a special cutter. The strips can have different thickness depending on the preferences of the manufacturer and the end user.

Potato processing. The potato strips are processed to remove excess starch and improve the color and texture of the fries. Processing may include washing, soaking in cold water and boiling.

Roasting potatoes. After processing, the potato strips are deep-fried until golden brown. Deep frying uses vegetable oil, such as sunflower oil or corn oil, heated to about 180 degrees C. During the frying process, the french fries are stirred periodically so that they fry evenly.

Adding spices and sauces. After frying, French fries are sprinkled with salt and other spices such as pepper, paprika, or garlic powder. In addition, french fries can be served with all kinds of sauces, such as ketchup, mayonnaise, mustard, etc.

Thus, the production of French fries is a process that includes several stages, ranging from peeling potatoes to deep frying potato pieces.

Nuggets are pieces of chicken meat that are coated in breadcrumbs and deep-fried until golden brown. Fish nuggets are produced using a similar technology. Let's take a look at the nugget production process:

Meat preparation. Chicken meat is cut into pieces and marinated in spices to give it the right taste.

Breading. Pieces of chicken meat are rolled in breadcrumbs, consisting of flour, salt, spices and other ingredients. Breadcrumbs allow you to get a crispy crust during frying.

Roasting. After breading, the pieces of chicken meat are fried in deep fryers until golden brown. Deep fryers are special equipment that allows you to quickly fry foods in fat. Typically, deep fryers have a large volume and a powerful heating system, which allows you to quickly maintain the desired temperature of the fat.

Drainage and packaging. After frying, the nuggets must be aged in special drainage equipment to get rid of excess fat. Then they are packaged in bags or containers and sent for sale.

Slicer (cutter). This is a special equipment for cutting chicken meat into pieces of the desired size and shape.

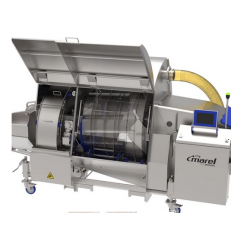

Coating equipment. It can be an automatic breading line, which includes various steps: mixing ingredients for breading, coating pieces of meat with breading mixture and drying the breading.

Fryers. As mentioned above, this is a special equipment for frying foods in fat.

Drainage equipment. After frying, the nuggets must be aged in special drainage equipment to get rid of excess fat.

Equipment for packing. It can be an automatic line for packing nuggets into bags or containers.

The production of nuggets can also use automated lines to feed ingredients, mix breadcrumbs, and control the temperature of the deep fry. This allows you to automate the production process and increase its efficiency.

Deep fryers are used to fry french fries, nuggets and fish & chips directly at catering points - such as fast foods, cafes or restaurants, street food enterprises.

General list of equipment required for the production of semi-finished french fries and nuggets:

- Potato peelers

- Potato cutters

- Deep fryers are a special device for frying food in oil. Electric fryers are commonly used, which have a large basket for immersing food in oil and adjustable temperature to achieve the desired degree of frying.

- A potato chip press is a machine that cuts potato chips to the desired shape and thickness.

- For the production of nuggets: meat cutter - used to cut chicken or fish carcasses into small pieces of the same size.

- A breading machine is a special equipment for coating pieces of meat with breadcrumbs. The machine can have different operating modes, for example, for breading in egg and flour or only in breadcrumbs.

- Slicer (cutter). This is a special equipment for cutting chicken meat into pieces of the desired size and shape.

- Drainage equipment. After frying, the nuggets must be aged in special drainage equipment to get rid of excess fat.

- Equipment for packing. It can be an automatic line for packing nuggets into bags or containers.

The production of nuggets can also use automated lines to feed ingredients, mix breadcrumbs, and control the temperature of the deep fry.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT