Autoclaves

Products’ shelf life is extended through high-temperature treatment. During the processes of pasteurization or sterilization, all microorganisms are killed. The main difference between these two types of processing is the different temperatures. In the pasteurization process, the temperature does not rise higher than 100°C and all vegetative forms of microorganisms (their growth and reproduction forms) are killed, while in sterilization a temperature higher than 100°C is maintained which kills all forms of microorganisms and their spores. To prevent containers from losing their hermetic seal, the heat treatment is carried out under high pressure created by liquid, steam, or a steam–air mix. To provide these conditions, autoclaves are used.

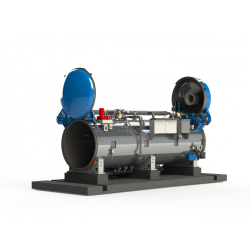

Autoclaves are essentially sterilizers that run in batch mode. They consist of a hermetically sealed tank capable of withstanding high pressure and temperature. Autoclaves generally ensure sterilization and pasteurization of products and they are also widely used in the making of all forms of canned foodstuffs, e.g. canned fruits and vegetables, marinated mushrooms, sauces, juices, and condensed milk.

Synonym: Autoclave, autoclave for canning, autoclave for canned food, steam autoclave, sterilizer, pasteurizer, steam sterilizer, dry heat sterilizer, canning machine, sterilization of food products, industrial autoclave, industrial retort, heat sterilization in containers, heat sterilization of canned food.

Applications

Autoclaves are mainly used for preparing canned meat from pork, beef, mutton, rabbit, poultry, and fish; canned mushrooms, marinated mushrooms, canned beans, corn, and peas, tomato sauces, juices, condensed milk and other canned dairy products, and baby food.

How the device works

Cold liquid enters into the device, is turned into steam, and then with the help of an automatic pump it is circulated from the lower part of the tank towards the irrigation system. Also, in order to prevent water from boiling, the pressure increases at the same time as the temperature. After this, the pump is activated to circulate the flow of water from the lower section of the tank towards the irrigation system.

As soon as the temperature reaches 120°C, the sterilization process for the foodstuffs is launched. The temperature regime and pressure is determined by the type of product and its amount, after which the supply of steam is completed and cold water enters in place of the hot water, which performs the function of cooling.

Whereby:

The autoclave method allows you to:

1) Eradicate all microorganisms and reducing spores to a minimum

2) Lower the time spent on production by several times

3) Reduce product-mass losses

4) Preserve the major share of vitamins and minerals.

5) Preserve foodstuffs in hermetically sealed packaging

6) Reduce changes to products’ taste and appearance.

Thanks to this:

Thanks to the high temperatures, all microorganisms are killed. High pressure allows you to move the boiling point, that is, liquids will boil at higher temperature values, which significantly reduces cooking time, and the hermetically sealed design reduces losses of product mass by preventing moisture from evaporating.

How autoclaves are classified:

|

|

Advantages |

|

|

According to the heating method used |

Gas

Electric

|

More economical due to the low cost of gas Price Easy to operate

Take up less space in your production area Have heat sensors allowing you to maintain the required temperature Are universal |

|

According to the heating medium used |

Electrically heated water

Steam

|

Price

Wider range of applications Economical Fast heating and cooling The most automated |

|

By design type |

Horizontal

Vertical

Shaking Rotating |

High performance. Products are heated evenly Can sterilize products in any packaging Loading and discharging can be automated Less time needed for sterilization Easy to use

Compact

Products are heated evenly Less processing time High quality of canned goods |

|

According to the mode of operation |

Periodic

Continuous operation |

Fewer maintenance personnel required

Less time for sterilization Canned goods are of high quality Low expense of steam and electricity. |

Autoclave design types

In vertical autoclaves water is heated through special tube-shaped electrical heating elements located in the interwall space in the lower part of the chamber.

In horizontal autoclaves, the role of the heating element is generally played by gas or spiral heat exchangers; the latter require little electricity, but they bring significantly higher costs than gas heating.

Shaking and rotating autoclaves ensure higher quality for any product and are used in making pultaceous and suspended products, but they are most in demand in the canning industry. They can process products regardless of the container type. They provide high output over a short amount of time.

Technical values for processing various types of products*

|

Product name |

Volume, L |

Processing time, minutes |

Pressure, MPa |

Sterilizing temperature, °C |

|

Canned meat |

||||

|

Beef stew |

0.65 |

125 |

0.25– 0.28 |

120 |

|

Pork stew |

||||

|

Meat with vegetables |

0.25 |

105 |

||

|

Canned fish |

||||

|

Fish in oil |

0. 5 |

80 |

0.34–0.4 |

115 |

|

Fish in tomato sauce |

||||

|

Canned vegetables |

||||

|

Green peas |

0.5 |

52 |

0.25–0.28 |

120 |

|

Canned vegetables (assortment) |

0. 65 |

28 |

0.15–0.17 |

100 |

|

Mushrooms |

||||

|

Braised mushrooms |

0.5 |

75 |

0.21–0.25 |

120 |

|

Marinated mushrooms |

1 |

50 |

0.22 |

116 |

|

Fruit preserves |

||||

|

Apples |

0.65 |

50 |

0.12 |

100 |

|

Cherries in cherry juice |

1 |

60 |

||

|

Beverages |

||||

|

Natural juice (except plum) |

1 |

40 |

0.12 |

85 |

|

Drinks made with apple and carrot pulp |

0.5 |

50 |

0.15 |

100 |

*this table gives average values; the given values will differ for the specific device and the instructions for its use.

Autoclaves can process containers made from the following materials:

Food-grade tins, aluminum, chrome steel. This container is the most durable and does not oxidize or affect the taste of products.

Glass is more environmentally friendly, plus it does not corrode or oxidize, it preserves the taste of products, it has a lower thermal conductivity, and it can be reused.

Polymer packaging based on polymeric and combined multilayer materials has low strength and is used for packaging sausages, ham, and pates.

Lamister packaging (steralcon) is made from multilayer foil and laminated with polypropylene. The advantages of this form of packaging are the wide variety of shapes and volumes, the lack of oxidization, the ability to withstand high-temperature processing and temperature fluctuations, low cost, and easy disposal.

Retort packaging consists of a multilayer polymer film (PET–foil–PP) with aluminum lamination. At present it is the most advanced type of packaging and is distinguished by puncture resistance, durability, minimal size and weight, heat resistance, and low cost.

In addition to the food industry, autoclaves are widely used in laboratories, medicine, cosmetology, and metallurgy.

Besides the kinds of autoclaves mentioned above, air sterilizers (dry heat) and pasteurizers are used.

In a dry heat sterilizer, microorganisms are eradicated by treating the product with hot, dry air (180°C) for a certain period of time.

Among the advantages of these machines are:

They feature a ventilation system, allowing you to control the temperature inside the chamber.

They bring lower expenses on energy and are easy to operate.

Low cost.

However, the sterilization process in air sterilizers requires more time and higher temperatures.

With the autoclave method for treating products, microorganisms perish at a temperature of 135°C maintained for a very short period of time without any significant changes to appearance, taste and physicochemical properties of the product.

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT