- New

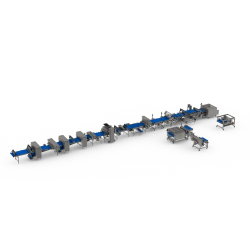

VENTILEX BREADCRUMB PRODUCTION LINE

Breading food products helps to seal in moisture when cooking, deep-frying or pan-frying.

Description

Breading food products helps to seal in moisture when cooking, deep-frying or pan-frying. It also provides a crunchy and delicious exterior, and the golden-brown color makes the food more attractive.

The consumption of breaded products has increased tremendously during the past decades. Also breaded products have evolved beyond the traditional crumb in terms of functionality, potential health benefits, flavor, texture, and appearance.

Rusk is mainly used as a filler, an ingredient for dried stuffing mixes or a binding agent in hamburgers, sausages, pies, and other compound meat products. It is also a carrier for flavors, colors and seasonings. Rusk is important for its absorption, texture and color properties.

Breadcrumbs, rusk and croutons come in many shapes and sizes. The majority of producers have defined very specific properties. These characteristics are based on the customer requirements for appearance (shape, structure and color), texture and technical properties (absorption, moisture content).

With great process knowledge and testing capabilities Ventilex features all that it takes to produce a product that lives up to these high standards. That is what leading company’s all over the world have discovered when choosing Ventilex as their partner.

VENTILEX BREADCRUMB, RUSK AND CROUTONS PRODUCTION LINES

Most breadcrumb, rusk and croutons processing systems rely on vibration, which is hard on the product due to the very high G forces involved, or on high volumes of airflow, which is frequently inefficient.

The Ventilex shaking Fluid Bed design, generates low-G force fluidization of product particles as well as predictable plug flow. This gentle shaking motion creates fewer fines, maximum output and less maintenance.

The complete Ventilex line consists of a bread mill, a fluid bed dryer/cooler, a gas burner, cyclone, recirculation, exhaust blower, cooling fan with filter, ductwork and fully automated controls.

Due to the unique low g-force of the shaking fluid bed design, Ventilex can offer a fully integrated fire protection system with fire detection and water spray nozzles directly in the dryer process space.

ADVANTAGES OF THE VENTILEX BREADCRUMB PRODUCTION LINE:

- Precise control of drying, or toasting, to ensure the product meets your specifications regarding color, shape and texture

- Processing of pellets, bricks, sheets, extrusions or loaves of bread

- Gentle shaking motion of the dryer creates fewer fines and less maintenance

- Incorporated safety solutions

- Reduced OPEX (Labor) with semi- or fully-automated production lines

- Data Logging and Traceability

- Hygienic design with high quality finish

- Automated cleaning system (CIP)

- Low energy consumption

110 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- New

- New

- New

- New

- New

- New

Artificial Rice Extruding Line / Instant Rice Making Machine

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT