- New

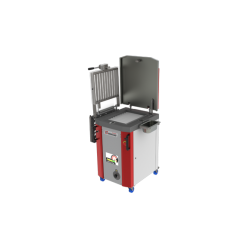

« Cut & Wrap » Production Line

PROFORM Extruders can produce a precise, regular format, which will allow your wrapping machines to function continuously and at high speed.

Description

PROFORM Extruders :

PROFORM Extruders can produce a precise, regular format, which will allow your wrapping machines to function continuously and at high speed.

Application/Product :

- Chewing-gum, Bubble-gum

- Chewy Candy / Soft Chews

- Caramel

- Toffee…

Capacity :

Up to 3200 kg/h

Format :

- Squares

- Rectanges

- Cylinders

Construction :

- Lacquered / painted steel

- Stainless steel

Options :

- Semi-liquid fillings or powder

- Metal detector…

A « Cut & Wrap » production line can be composed of the following :

- An Extruder (single color) or a Co-Extruder (two colors)

- A Cooling Tunnel

- An output table (connection to the wrapping machine)

It is possible to produce identical formats or different ones simultaneously, to respond to your marketing needs :

- Format changes are quick as the production parameters are memorized.

- The product is cooled after forming, to directly feed your cut & wrap machine.

- It is possible to simultaneously extrude products of different colors and flavors (co-extrusion)

- « Cut & Wrap » lines can also handle products with semi-liquid or gelled fillings.

- Maintenance is minimal and easy access

Progressive investment possible :

Proform can supply a production line (extruder and cooling tunnel) that can feed your wrapping machines functioning at different capacities.

A PROFORM « Cut & Wrap » line offers maximum production flexibility to manufacturers; according to your needs, the Extruders or Co-Extruder of the ME or FE series can continuously mix flavor and color into a neutral paste.

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT