- New

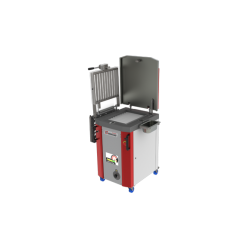

Industrial Cutter K 206

A fast and smooth reduction and emulsification of the product thanks to the knife head with 8 knives and the flow dynamically shaped lid.

Description

The Seydelmann High Efficiency Cutter guarantees a fast and smooth reduction and emulsification of the product thanks to the knife head with 8 knives and the flow dynamically shaped lid. The components of all Seydelmann Machines comply with the upto-date technical development and contribute to an increase in product quality.

Applications

Besides the production of boiled-, dry- and cooked sausage, the universally applicable machine is suitable in particular for the chopping, mixing and emulsification of fresh meat, pre-cut frozen meat, cooked meat, fish, vegetables, meat substitute products made from plant-based proteins, fruits, confectionary goods and other edibles at temperatures from -12 °C (10 °F) up to 85 °C (185 °F).

Machine design

The machine frame of the K 206 is almost entirely made of solid stainless steel. All edges are rounded and all surfaces are polished very precisely and designed with a slope enabling cleaning water to drain completely from all surfaces. The embedded covers and the closed bottom with ventilation prevent pollution and water from entering the machine. The knife hood is flow dynamically shaped. Hardly any unchopped product residue is left in the cover. The gap between the knives and the cover or the bowl is very small. Solid construction for best possible smooth operation associated with the double-walled cover construction ensures optimal noise-reduction.

Facts

Bowl content: 200 Liters

Weight: 2600 kg / 5732 lbs

Loading options: BW 120, BW 200

Power of motor:

rasant, ultra: 67 kW / 90 HP

rasant v, ultra v: 90 kW / 121 HP

rasant vs, ultra vs: 105 kW / 141 HP

AC-8: 100 kW / 134 HP

Standard equipment

- Operation via cross lever switches

- Changeable and balanceable knife head

- Hydraulic main cover and ejector

- See-through noise absorbing cover made of special plastic

- Separate electrical cabinet made of stainless steel with integrated main switch

- Pneumatic locking of knife shaft arm

- Switch-off for temperature and operating time

- Temperature sensor

- Noise insulation

- Water drain screw

- Greasing point

Additional equipment

- Hydraulic loading device

- Hydraulic absorbing cover

- Control of unbalanced state

- Various knife systems

- Up to 9 switch-offs for temperature and operating time

- Variable adjustment of knife speed (only with AC-motor)

- 4 bowl speeds, steplessly adjustable (only with AC-Motor)

- Water nozzles with water meter

- Liquids dosing system with nozzle

- Fast clamping nut for knives

- Ejector with variable speeds

- Lock of noise absorbing cover

- Cover damping for noise absorbing cover

- Noise insulation version

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT