- New

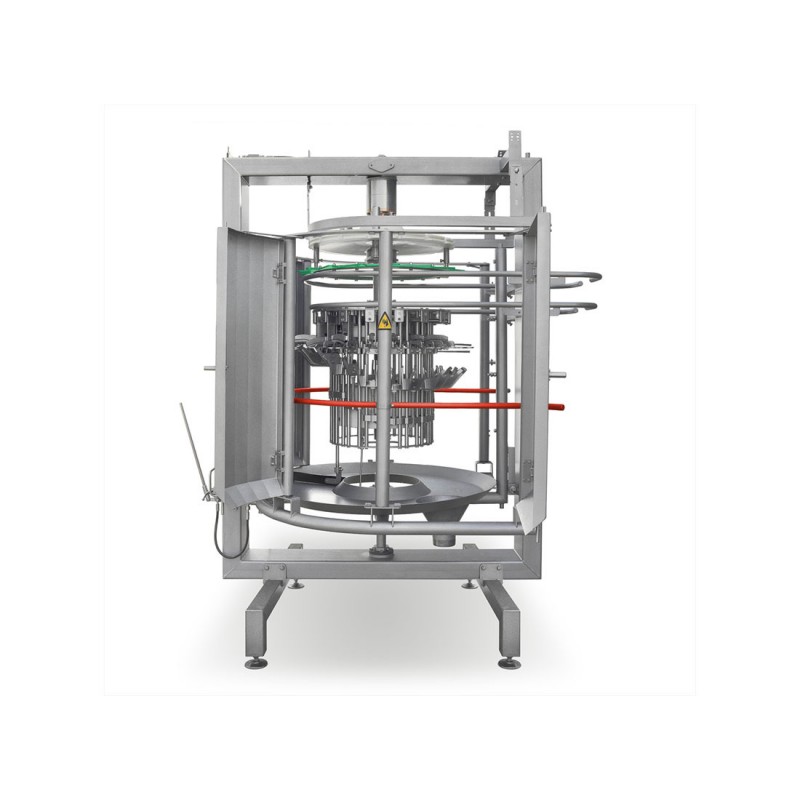

Opening machine

Meyn’s opening machine, with its patented scissors mechanism, can handle a wide weight range within one machine setting.

Description

This is partly due to the fact that the processing unit is uniquely positioned against the keel bone before cutting. This positively affects product quality as the breasts remain perfectly covered with skin. The typical design of the centering bracket results in a very limited number of damaged guts.

The spring-loaded cutting mechanism protects the scissors from overload damage. Combined with the knife design, this makes the scissors very reliable resulting in a highly uniform and consistent performance. Moreover, the scissors are virtually maintenance free, further reducing the TCO of this machine.

Operations

The opening machine is placed in a 180 degrees curve of the overhead conveyor of the EV line, often directly after the vent cutter. Birds are hanging in shackles of the overhead conveyor and are guided into the infeed section of the machine with the back of the birds towards the centre of the machine. Sets of static and spring loaded guides position the birds into the processing units of the opening machine. The birds are held in position by the lower part of the processing unit, two side supports lift each bird and pushes it against a centering bracket placed between the legs of the bird.

Next, the lower (blunt) part of the scissors is guided through the vent hole into the bird until it rests against the breast bone. This is done in such a way that the intestines are not damaged. The following step is the lowering of the upper (crenellated) knife, cutting the abdominal skin. Finally the bird is released from the unit.

The processing unit is cleaned after each cycle using spray nozzles. Optionally a high pressure spray system is fitted to cleaned the knife and centering bracket.

Options

Rigid shackle model

High pressure spray system

Highlights

Patented cutting mechanism, ensuring a consistent and exact cut independent of bird live weight

Non wearing cutting blades, always a clean cut, reduced maintenance and downtime

A very reliable performance due to the spring-loaded mechanism

Cut is positioned relative to keel bone, no uncovered breasts

Exact positioning of the bird in the machine resulting in reduced intestine damage

Large weight range can be processed within one machine setting

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT