- New

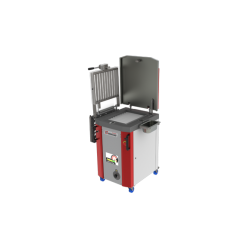

MS80ie Industrial Cheese Cuber

The MS80ie Industrial Cheese Cuber is a breakthrough in block reduction technology.

Description

Overview

The MS80ie Industrial Cheese Cuber is a breakthrough in block reduction technology. Designed to address concerns about floor loss, wire break detection, cleanable design and inline construction. It remains a critical part of the converting process, producing very clean-cut cubes that create the best shred and dice appearance. The machine can process blocks, wheels, and loose trim cuts. Servo actuators maximize production with a custom profiled movement. This allows the machine to adjust the cut force and speed for each cheese resulting in faster production, fewer wire breaks and better-quality cubes. Interchangeable cutting harps are used to alter the cube size which ultimately changes the shred length. Contact Marchant Schmidt for a quote on an industrial cheese cuber to fit your food processing line.

- Excellent product containment

- Electric servo actuators maximize production

- Combination wire/knife harp for cut quality

- Wire break detection

- Easy cleaning with removable sections

- Urethane belts for better hygiene

Specifications

- Cycles per Minute: 3

- Production Capacity: 7,200 kgs/hr / 15,000 lbs/hr

- Electrical: 400 – 575 VAC / 45 FLA

- Broken Wire Detection: Yes

- Actuator Power: Electric Servo

- Cutting Method: Combination – Wire & Knife

- Cycle Start: Automatic with Infeed Conveyor

- Maximum Cut Chamber: 180 x 280 x 360mm / 24.5 x 16.5 x 9.29″

- Cube Discharge: Into MS3000 Metering Conveyor

- Cheese Blending: Alternating Full Block

- Block Preparation Rollers: Standard

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT