- New

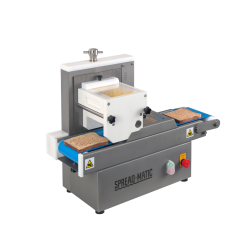

BVK 2000S

Contract price

Cutting and packaging of soft and hard sugar masses, chewing candy and chewing gum masses.

Reference:

BVK 2000S

UPC:

EAN13:

New product

Description

Cutting and packaging of soft and hard sugar masses, chewing candy and chewing gum masses. Resettable to plate feeding for formed candy (optional).

Method of operation:

- Drive of the forming roller pairs is performed via a servo-controlled separate servo-motor for infinitely variable adjustment of the product lengths and for uniform rope conveyance.

- Wear-resistant materials and coatings for all rope-guiding components.

- Rope monitoring between the forming rollers and rope cutter.

- Oscillating cutter for a straight, smooth cut – integrated stripper on the cutter.

- Upon cutting, transfer of the product is effected into the short duplex feed chain with a sufficient dwell time for shape stabilization prior to transfer into the packaging material tube.

- Constant lubrication of the cutter drive, splash lubrication – no oil circulation.

- High cutter tool life and antiadhesion properties due to the special coating.

- Integrated components for optional water cooling of the rope cutter.

Benefits:

- Easy size changes due to infinitely variable adjustment of product lengths, heights and pack lengths, as well as rapidly changeable parts for changing the product and pack widths.

- Large size ranges covered. High output without changing the crosssealing rollers or driver chain.

- Solid product-contact components for constant production conditions after size changes.

- Possibility of on-site combination of the rope feed with our infeed system for preformed candy.

- Automatic reel changing at end of reel and with web tear monitoring.

- Easy operator control and size management via touch screen.

Technical Data:

Product dimensions:

Height: 2 - 15 mm

Width: 12 - 30 mm

Length: 18 - 120 mm

Pack dimensions: min. 40 x 15 mm, max. 200 x 50 mm

Output: up to 1,600 ppm

Machine dimensions: 2,433 x 1,384 x 1,640 mm (L, W, H)

Technical data are subject to change

103 other products in the same category:

- New

Provatec 760-50 790 E C-Frame

- New

Automatic hamburger forming machines C/E HF

- New

Cutting of croquettes and meatballs maker

- New

MH / MA Manual Burger / Meatball Formers

- New

Cube Sugar Factories - R 925

- New

Vertical form fill sealing

- New

Forming & Moulding machines

Automatic meat ball and fish ball making machine (FMB-60)

Contract price

Automatic Meat Ball And Fish Ball Making Machine (FMB-60)

- New

The Maxima Automatic Dough Roller

- New

Automatic croquettes and meatballs machine Mod. FA

- New

Automatic Egg Roll Machine (ER-24)

- New

Combined line Premium K with PRIMUS 4-POCKETS

- New

Moulding machine for caciocavallo mod. SP21/CC

- New

Croquant - Embossing and Forming

- New

Spinach Portioning Solutions – Blanched – Cooled Spinach

- New

Depositor The ServoForm Mini

- New

FS 37 Form, fill and seal lines

- New

Eccentric rounder + By-pass

- New

FME 50 (Rotary Form-, Fill- and Seal Machine)

- New

Burrito Forming Machine (BR-1500)

- New

Dough Rounding Machine Simplex Rounder

- New

FSL 48 Form, fill and seal lines

- New

PET blowing machine Combi200

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT