- New

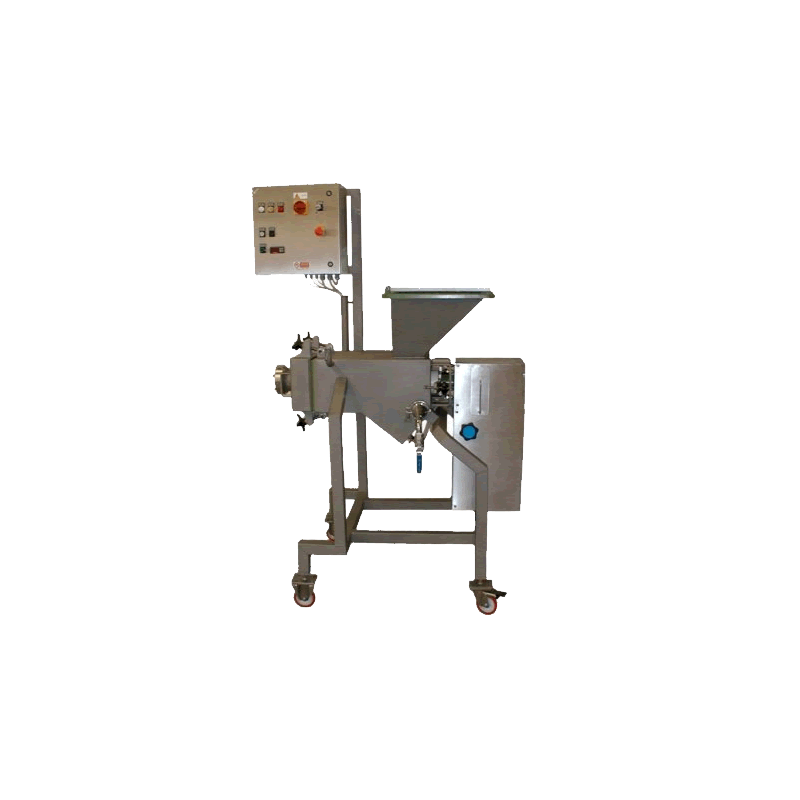

Extruder mod. EM 2000

Hourly output up to 800 kg

Description

The Extruder mod. EM 2000 is a machine suitable for the production of cylindrical products having weights from 300 gr to 3 kg and, eventually, also higher weights. This machine is suitable to extrude the following products:

MOZZARELLA FOR PIZZA – MELTED CHEESE – FOODSTUFFS

The machine can be fed either by a continuous stretching machine or by an Almac steam stretcher mod. FV. Pasta filata is introduced into the in-feed hopper and by means of two counter-rotating augers it’s transported to the conveyor cone, to which the extruding pipe is connected and which can be replaced according to the product desired shape. The EM 2000 augers body is surrounded by a double jacket heated by electrical heating elements for keeping pasta temperature constant. Furthermore, as the extruder is always coupled to a clipping machine, it is equipped with all necessary controls for the coupled operation of the two machines.

Construction features

- Machine completely built in AISI 304 stainless steel and plastic materials certified for the food use.

- Parts in contact with the cheese are coated with non-sticking material.

- The augers chamber is equipped with water double jacket, heated by an electrical heating element.

- Dismountable stretching water discharging filter.

- Dough feeding augers built to be easily dismantled without using any tool.

- Adjustable augers rotation speed.

- Motorizations protected by AISI 304 stainless steel cases.

- Motorization equipped with spacer to allow the cleaning between the motor and the moulding chamber.

- Motorizations equipped with electronic inverter.

- Connections with bending radius built in such a way to avoid any stagnation point.

- PTC probe for detecting the water temperature into the double jacket

- Watertight electrical control panel with IP 65 protection degree, built in AISI 304 stainless steel, complete with electronic devices for the processing speed adjusting and the operator’s safety control.

- Dismantling easiness of the movable parts without using any tool and complete inspection possibility.

- Set of safety sensors against accidents to start the machine stop up in case of guards opening

Advantages

- Possibility to mould cheeses with different diameters and weights by the simply replacing of the extruding pipe.

- Controls simple use.

- Easy disassembly by the operator of parts in contact with foodstuffs without the help of any tool for facilitating the washing and sanitation operations.

Technical data

Extruder mod. EM2000

- Length (mm) 1130

- Height (mm) 2000

- Width (mm) 800

- Feeding height (mm) 1.475

- Discharging height (mm) 1.050

- Augers diameter (mm) 150

- Weight (empty machine) (Kg) 300

- Hourly output (Kg/h) 100 – 600

- Line tension (V) 400

- Auxiliary circuits tension (V) 24

- Frequency (Hz) 50

- Installed electrical power (kW) 3

- Absorbed current (A) 7.5

21 other products in the same category:

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT