- New

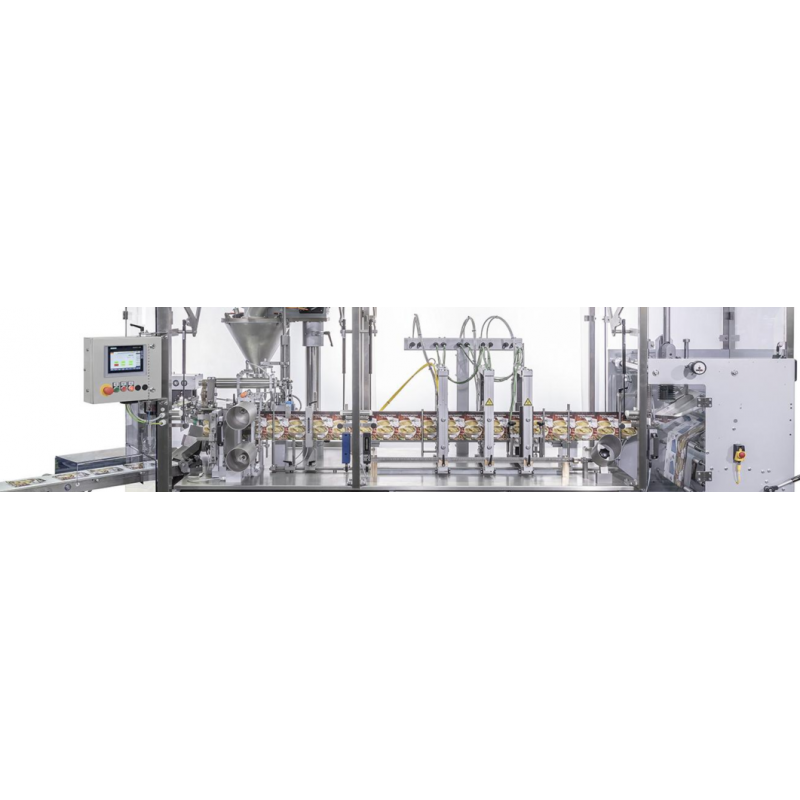

FME 50 (Rotary Form-, Fill- and Seal Machine)

An intermittent operating rotary machine to manufacture various types of pouches: 3sides or 4sides sealed pouches, stand-up pouches and bottom fold type pouches.

Description

The FME 50 is an intermittent operating rotary machine to manufacture various types of pouches: 3-sides or 4-sides sealed pouches, stand-up pouches and bottom fold type pouches.

Applications

Food, Pet Food, Nonfood, Seeds, Pharmaceuticals, Household and Personal Care.

Flexible possible applications

- Interface for multihead scale or auger doser

- Single sealing frames with quick and simple format changeover

- Folding wedge adjustment for bottom fold width (manual execution)

- Exemption of the sealing tools during machine stops

- Format changeover in less than 15 minutes

- Central gripper adjustment for pouch width (manual execution)

- Quick commissioning – plug & play

- Simple machine operating - short training

- Compact machine measures - less production space required

Specifications

Pouch size [mm]: Width 50 - 170, Length 70 - 210

Machine output [Pouches/min.]: up to 80 (depending on filling characteristics and pouch size)

Packing material: sealable film

Design: for processing dry products

Safety equipment: acc. to the international safety regulations e.g. CE , UL, OSHA

Power consumption [kVA]: ca. 2 (Depending on configuration. Technical modifications reserved)

Electricity supply: 3 x 400/230V + N + PE, 50/60 HZ

Voltage [V]: 400 / 230 / 24

Air consumption: ca. 200 - 300 Nl/min., 6 bar 1)

Machine dimensions L x W x H [mm]: ca. 3.700 x 1.250 x 2.010 1)

Standard equipment

- Single sealing frames - quick and easy format changeover

- Central gripper adjustment (manual operated)

- Decentral control structure for all motion drives

- Empty pouch discharge on station 8

- 7“ HMI

- Discharge belt 1.100 mm

Optional equipment

- Stand-up pouch equipment

- Zipper integration

- Auger doser and/or multihead scale synchronization

- Double vertical sealing and cooling

- Printer synchronization

- Preparation for dust extraction

- Swiveable top sealing for easy maintenance

21 other products in the same category:

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT