- New

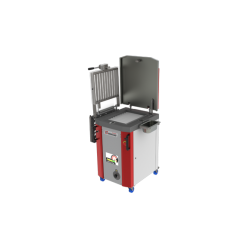

ES 135 Automatic cheese cutting machine

Contract price

The new machine generation by HAJEK, designed for cutting of round and square cheese loaves into strips, complies with the lates hygiene and safety requirements as per ISO 9001 and CE.

UPC:

EAN13:

Sold By:

view_listView more products of this seller

Description

Moreover, HAJEK's concept of balcony construction (driving elements separated from the product slide) was persistently pursued.

The high flexibility of the operating sequences and cutting data is provided by the programmable electronic control, a well-proved core piece which receives special attention by the HAJEK technicians.

Great efforts were made with regard to an easy control and operation. The setting of the cutting data, f.ex., is based on most simple, logical criteria. The high flexibility of our company, demonstrated again in this new machine generation, enables us to realize your special wishes and requirements.

To reach an optimum capacity and cutting accuracy for the various cheese qualities, shapes and dimensions, the machine can be extended by a number of accessories which emerged from practical experience:

The high flexibility of the operating sequences and cutting data is provided by the programmable electronic control, a well-proved core piece which receives special attention by the HAJEK technicians.

Great efforts were made with regard to an easy control and operation. The setting of the cutting data, f.ex., is based on most simple, logical criteria. The high flexibility of our company, demonstrated again in this new machine generation, enables us to realize your special wishes and requirements.

To reach an optimum capacity and cutting accuracy for the various cheese qualities, shapes and dimensions, the machine can be extended by a number of accessories which emerged from practical experience:

- Drive motors with variable speed to ensure the maximum working speed for the respective product

- The patented cutting angle adjustment of the cutting edge ensures a perfectly straight cut also of the first and end pieces

- If combined with the cutting angle adjustment, the cutting edge can be swivelled out to both sides to facilitate the cleaning.

- Elimination of first and en pieces.

- Countertipping device for cheese loaves to have the first halfof the cut strips be also lying on the long cutting face.

- Lengthwise strip alignment for a betterrectangular further processing.

- Automatic charging by means of conveying belt or unstacking device

- The Optimat programme provides for an optimum exploitation of loaves with different diameters by input of a width tolerance of the strips.

181 other products in the same category:

- New

PC-82 / PC-22 Meat Mincers (Grinders)

- New

A machine for sawing duck legs and shanks

- New

SC-3AR 3-axis ultrasonic food cutting machine

- New

Automatic feed corn cutter ACC (CCM)

- New

Refrigerated meat mincer with automatic feeding C/E901 R

- New

Industrial cutters KN-200, KN-330, KN-550, KN-750

- New

Tenderizer and stripes cutting machine TSC 500

- New

Automatic Hind Foot Cutting ABSA-800

- New

SUPER-WAKADAISHO All-in-one model WB874AS

- New

Heavy Duty Commercial Meat Mincer FW N32/98

- New

Standard pneumatic cutter with matrix mode PS01

- New

High Speed Dicing Machine (AD-1000 Series)

- New

Automatic Cutting Line for Pork Middles AMBL-650/1100

- New

Cutting of croquettes and meatballs maker

- New

Cheese-cutting machine CHEESMAXX 200

- New

BANDOTARO All-in-one model MXB584

- New

Multipurpose Vegetable Cutting Machine (ACD-800)

- New

Vegetable cutting machines GSM MULTICUT 240

- New

Universal mixing and cutting machine

- New

SC-2AR ultrasonic cutter for round food

- New

Vegetable cutting machines ANLIKER XXL PRO

- New

Multifunctional cheese-cutting machine CHEESIXX

- New

- New

Vegetable cutting machines ANLIKER XXL

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT