- New

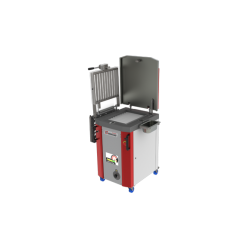

extruCut 9k

All of our systems are manufactured in a compact design. Our latest models are equipped with integrated electronics, Siemens Simatic and a servo control.

Description

The EXTRUCUT 9K - a highly flexible platform

a globally unique drive system

hygiene optimized using only one helical mount

exchangeable worm casing

operation and discharge occurs on the same site:

therefore loading up is possible from three sides

servo operated drive concept

New, revolutionary cutting systems

Cutting system without knives and discs.

Therefore no metal abrasion; almost no wear.

Rejection of foreign objects such as cartilages, residual bones,-fractions, sinews and rinds, plastics, and other foreign objects.

Depending on the hole size, an output of up to 100% can be achieved.

Meat cutter

meat cutter for all kinds of meats.

Processing of slightly frozen blocks of up to -2°C to -3°C possible.

Loading of the grinder with ramp (for standard cutter trolleys), with conveyor or with big-box loading.

Digital control for easy operation

Pictograms (self-explaning).

Permanent logging of current; upon request temperature logging with direct wifi connection to visualize the information on your computer.

Reduction of service costs by wifi and direct access on PC.

Program parameters can be adjusted.

Complete operation through the control-panel. Exceptions: ON/OFF, Reset and Emergency Stop.

Automatic dry-run protection in case the meat supply is stopped.

| Machine dimensions LxTxH in kg |

Voltage | Recommended protection |

Internal protection | Recommended cable diameter for machine connection |

Output per hour/power consumption in kW |

|

| extruCut 9k | 3.500 x 1.850 x 2.400 mm / ca. 2.900 kg |

3 x 400 V / 50 Hz Europe 60 Hz American / 3 pH |

3 Ph + N + PE 125 A |

A3 + N + PE 120A | 5 x 35 mm² | 6.5 - 9 Tonnen / 55 kW |

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT