- New

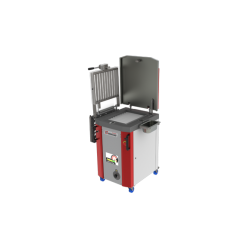

Vacuum Bowl Cutter 30 Ltr.

“The BEST Series” is the further developed intelligent technology of Meat Machines in an outstanding hygienic design to increase both the quality and ease of use of a Bowl Cutter.

Description

“The BEST Series” is the further developed intelligent

technology of Meat Machines in an outstanding hygienic design to increase both the quality and ease of use of a Bowl Cutter.

With the background of more than 85 years of experience, in developing and manufacturing food machines, “THE BEST SERIES” offers a world leading performance and a huge number of available options.

The machine for teaching and research.

A bowl cutter of this type with a bowl volume of only 30 litres is THE BEST for teaching and research purposes.

With its standard vacuum installation new recipes can be either produced or developed under the same conditions as later in the production with larger machines. The economical advantages of vacuum technology (more protein broken up, better binding capacity, longer shelf life) have become more and more important. Additionally to the already extensive basic equipment (drives for knife shaft and bowl with reverse drive etc.) various options can be added:

The Vacuum Bowl Cutter 30 litres is also available as Vacuum-Cooking-Bowl-Cutter. The cooking installation allows production of cooked products in a faster, more efficient and more economic way.

The high speed package with stronger frequency converter transforms your machine into a high speed bowl cutter with a speed of up to 156 m/sec at the knives.

Adding nitrogen and water shortens the production process, while at the same time storage and transport of flake ice is no longer necessary. The cooling effect is reached without opening the lid. Liquid as well as gaseous nitrogen is fed into the bowl through a special nozzle. At the same time, the amount of water required can be added through a separate feeding tube, steered either manually or by computer. Authorized special companies can complete the nitrogen preparation including the required exhaust directly at the customers place.

- Made from: Stainless steel

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT