- New

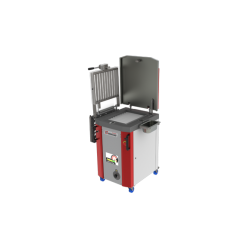

Vacuum bowl cutter SM33L

For improved production, our vacuum bowl cutters enable you to make sausages under vacuum.

Description

For improved production, our vacuum bowl cutters enable you to make sausages under vacuum. This achieves results of an even higher quality. Higher protein digestion, better binding in the meat, optimised product shelf life due to reduced oxidation, and longer colour retention are just a few of the advantages that our vacuum cutting mixer provides for your meat processing. At full power and performance diversity, the noise level of the machine is extremely low.

- Versatile machine types for different batches

- Sausage production with vacuum technology

- Removable baffle plate allows variable cutting chamber sizes

- Easy operation

- Robust, maintenance-free water ring vacuum pump ensures minimal water consumption

Datasheet:

Electrical data:

- operating voltage (standard) - 400V/50Hz

- rated power (incl. vacuum pump) - 47 kW

rotation speed:

- knives head - 40...5000 min

- mixing (forward and backward) - 40...500 min

- bowl drive (variable speed) - 5...18 min

vacuum pump, separate freestanding unit:

- pump type - water ring

- throughput - 120 m3 /h

- water demand (only during evacuation) - approx. 5,5 l/min

- water pressure - 5 bar

Cooking/cooling system (preliminary data):

- water consumption during cooling mode - approx. 50 l/min

- water pressure- 2...3 bar

- steam consumption during cooking mode typ. - 15 kg/batch

- steam pressure/temperature - 1...2 bar/120 C°C...133°

noise level (preliminary) at no-load operation (full speed, vacuum cover closed, no vacuum) - 78 dBA

optimum batch size:

- boiled sausages - 96 kg

- cooked sausages - 84 kg

- raw sausages - 54 kg

weight :

- without unloader - 2070 kg

- with unloader - 2180 kg

- hydraulic loader - 350 kg

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT