- New

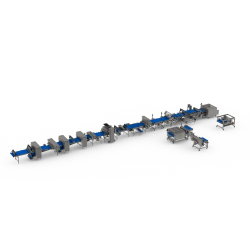

VARIOFLEX M 700: the coppact pastry make-up line

For a large variety of pastry products.

Description

For a large variety of pastry products.

Due to its compact design, the VARIOFLEX M 700 is ideal for small and medium-sized bakeries. Nevertheless, a wide variety of bakery products can be produced. Cut, folded, coiled, filled or punched products – the possibilities are endless.

The standard calibrating head creates a continuous dough sheet with accurate and consistent thickness. The motor-driven guillotine provides high cycle rates and precise cutting accuracy. However, the VARIOFLEX M 700 always works silently. The cutting frame, which is part of the basic equipment, offers customers the option of using up to two cutting rollers and a punching tool at the same time. Therefore it is possible to produce various Danish pastries and other pastry products within a tight production schedule without unnecessary delays thanks to a quick changeover concept.

Controlling the VARIOFLEX M 700 is quite simple because of its implemented intuitive control concept via a touch screen display. Another advantage is its digital control. Up to 100 different production programmes can be stored and exported to external storage devices via a USB interface.

TECHNICAL DATA

Installation area (LxWxH): ca. 5,200 x 1,360 x 1,600 mm

Conveyor belt table height: 900 mm

Conveyor belt table width: 700 mm

Conveyor belt width: 650 mm

Dough sheet width net: 600 mm

Conveyor belt speed: 0.5 - 5 m/min

Capacity cross cutting: 100 strokes/min

Capacity punching: 30 strokes/min

Number of rows filled: 1-6

ADVANTAGES

- Easy and quick product changeover without the need for assembly tools

- High product variety by specialised, easy-to-use accessories

- High weight accuracy of the products due to exact control of the cutting length

- Flexible design due to different table lengths

- High output (high cutting frequency)

- Quick and easy handling due to intuitive operating concept and the option of storing 100 programmes

- Comfortable data backup by USB interface

- Long service life due to robust stainless steel design

- Low noise level due to motor-driven guillotine (≤75 dB)

- Easy to clean due to hygienic design and good accessibility

OPTIONS

- Various filling units

- Various tools for cutting and decorating

- A wide variety of punching tools and guillotine knives

- Moistening units

- Strewing units for different materials, such as sugar, seeds, spices, etc.

- Coiling-in rollers for Danish whirls

- Folding ploughs in different sizes, shapes and numbers of rows

- Dough piece deposition

110 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

AUTOMATED DOUGH PROCESSING LINE AND TRAY LOADING SYSTEM HATT

- New

- New

- New

- New

- New

- New

Ricotta System for High Protein Cheese Production - HOMMAK R-HM10

- New

- New

Artificial Rice Extruding Line / Instant Rice Making Machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT