- New

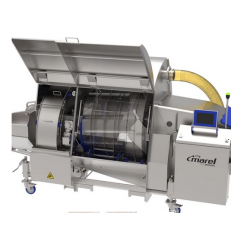

The Drum Breader ADB

Our drum breader was developed specifically for challenging products.

Description

Function

With our drum breading machine, we also master the top tier of breading: Genuine homestyle coating of irregularly shaped products such as bone-in products. So you don’t need to do without a breading when it comes to drumsticks, chicken thighs, etc., we’ve developed a special breading flour distribution and sprinkling system for hard-to-coat products. Whether dried spices, herbs, or flour: Our drum breading machine will apply coating with a fine or coarse grain to your product in a gentle way or with intense tumble coating, just the way you’d like it.

Features

Our drum breader speaks for itself thanks to an innovative breading system for irregularly shaped products(e.g., bone-in products like chicken drums or chicken tenders). It allows for an especially gentle and intense application, including a clump sifting and blower air circulation system.

Details

Coating with fine or coarse breading

Dried spices, herbs, or flour

Particularly suitable for completely coating irregularly shaped products (e.g., bone-in products like chicken drums, chicken tenders, etc.)

Innovative breading flour distribution and sprinkling system

Gentle pre-coating and intense tumble coating in one machine

Extremely gentle breading flour circulation system without spotting

Integrated clump sifting system

Innovative blower air circulation system

Hygienic design for top product safety

Easy operation and cleaning with maximum safety

Our drum breader

1: Drum

is optimized for small and large batch sizes, plus variable drum speed and efficiently attached bafflers.

2: Filter system

separates clumped-up residues from the coating material and constantly maintains the consistency and quality of the material.

3: PLC control

controls the machine in a smart and user-friendly way through a touch panel with functions like recipe management, etc.

Optional

4: Lateral supply and refill funnel

allows for ergonomic and automatic equipment filling.

5: Spindle height adjustment

sets the height of the entire plant by means of a handwheel, without the use of tools

10 other products in the same category:

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT