- New

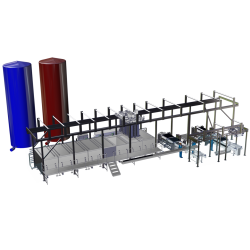

RKM – RONO UNIVERSAL COOKER/MIXER

This RKM process system is designed for the production of soups, stews, sausage, meat products, rice, noodles, baby food, many other products.

Description

This RKM process system is designed for the production of soups, stews, sausage, meat products, rice, noodles, baby food, many other products. The cooking process is possible by means of direct steam injection. Furthermore the system can operate under vacuum and overpressure.

The RKM – Batch Cooking/Mixing System is designed for the production of soups, stews, sausages, gourmet salads, meat products, baby food, pet food, pasta, rice, etc..

The system operates under vacuum and its high efficiency enables short production times in high capacity per hour based on functionalities. It ensures optimum retention of colour, flavour and structure in your product without any risk of caking or cooking loss and with extra fast CIP/SIP cleaning.

The modern PLC system is easy to operate and allows both semi-automatic and manually operation to manage recipe’s data. The repetitive process parameters lead to very reliable productions with highest quality performance. The process container works at 3 positions: 0° loading, 30° mixing and 100° emptying.

As standard, the mixture is designed to be filled and emptied into standard containers via a lifting and tilting mechanism. The various ingredients could be metered directly from hop-pers via an inductive fl ow meter or/and a mass fl ow meter.

Benefits

- Solid design - modular and flexible

- Versatile process functions in one machine

- Customized high quality products

- Maximum production capacities per hour

- Made in Germany

- Skid mounted unit - piped and wired

- Tailor-made solutions

- Easy to load and emptying

- Easy maintenance and operation

- Recipe control and highest process safety

RONO RKM Batch System

Types & Variations

Container sizes

Depending on the desired product and the requirement on the final product condition and consistency as well as the desired hourly capacity, container sizes of 200 to1200 ℓ are available.

Process options

The RONO RKM Batch cooking System allows a variety of process options depending on the available raw materials.

Modular Design

Extensions to the vacuum process plant are also possible and can be added at any time, due to the modular design.

Technical Data

|

Model |

RKM 200 |

RKM 400 |

RKM 600 |

RKM 800 |

RKM 1000 |

RKM 1200 |

|

Vessel volume [ℓ] |

200 |

400 |

600 |

800 |

1000 |

1200 |

|

Charge size [ℓ] |

60–160 |

100–300 |

100–400 |

150–600 |

250–800 |

350–1000 |

|

Charge/ hour |

2–4 |

2–4 |

2–4 |

2–3 |

2–3 |

2–3 |

|

Stirrer motor [kW] |

5,5 |

6,5 |

7,5 |

7,5 |

9,2 |

9,2 |

|

Stirrer speed [1/min.] |

3–60 |

3–60 |

3–60 |

3–60 |

3–60 |

3–60 |

|

Agitator positioning |

bottom |

bottom |

bottom |

bottom |

bottom |

bottom |

|

Tilt motor [kW] |

0,37 |

0,37 |

0,55 |

0,75 |

0,75 |

1 |

|

Vacuum pump [kW] |

0,75 |

1,5 |

3 |

3 |

3 |

4 |

|

Vacuum pump [kW] in case of direct steam |

1,5 |

3 |

5 |

5 |

5 |

5 |

|

Vacuum Water capacity [ℓ/h] |

80–390 |

100–390 |

130–660 |

130–660 |

130–660 |

260–1500 |

|

Weight max. [Kg] |

3500 |

4000 |

4500 |

5600 |

6000 |

6500 |

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT