- New

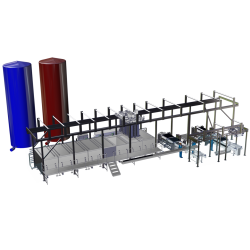

Batch Cooker JellyCook™

The JellyCook™ batch cooker brings the benefits of starch-free production of gummies and jellies

Description

The JellyCook™ batch cooker brings the benefits of starch-free production of gummies and jellies to companies operating in healthcare, supplement and confectionery markets. It is designed to feed a 50kg/hour ServoForm™ Mini depositor.

Integrated system

JellyCook™ is a flexible, integrated batch weighing, mixing and cooking system. Products using gelatin, pectin, carrageenan or blends as the gelling agent can all be handled.

Output options

The range of semi-automatic JellyCook™ units offers 10 to 30kg batch sizes, with outputs up to 60kg/hour; a high output model with two cookers will produce 100kg/hour.

Easy to operate

Simplicity is a decisive benefit with all operator actions prompted by messages on the HMI screen. The system consists of an oil-heated stainless steel cooking vessel with a variable speed mixer / stirrer, a reservoir tank and a support frame with operator platform.

Configurations:

JellyCook™

Standard module consisting of one cooker and one reservoir tank

Output of 30kg/hr based on Pectin “all in” recipe

25min cook

Optional pumped discharge to depositor

JellyCook™ Max

Higher output version of JellyCook™ consisting of two cookers feeding into a single reservoir tank

Output of 60Kg/hr

Optional pumped discharge to depositor

JellyCook™ Duo

Configuration for gelatin or two colour operation

Consists of two modules, each containing a cooker and reservoir tank

Modules can be operated in sequence or together depending on the products and/or throughput required

Features:

Outputs up to 60kg/hr (10-30kg batches)

Variable speed mixer / stirrer

Even cook temperature

Intuitive HMI with guided cooking prompts

Mounted on a hygienic stainless steel frame with operator access and storage areas

Suitable for floor or mezzanine installation with manual, pumped or gravitational transfer to the depositor

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT