- New

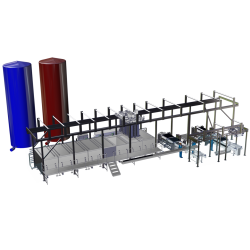

BM50 TOP MULTIFUNCTION BENCH

MULTIFUNCTION BENCH TO COOK, CONCENTRATE IN VACUUM, FRY LIGHTLY, MIX IN VACUUM, COOK AT ATMOSPHERIC PRESSURE, PASTEURIZE/STERILIZE UP TO 135°C.

Description

What can I do:

cook/concentrate in vacuum at 50°C

mix in vacuum

cook/concentrate in atmospheric pressure up to 140°C

fry

braise

candy

cook/scald in water or other liquid at atmospheric pressure or under pressure up to 135°C

steaming at atmospheric pressure or under pressure up to 135°C

sterilize up to 135°C with calculation of the algorithm F0, F100 and F71

sterilize up to 135°C with manual setting of time and temperature parameters.

Ideal for production of: jams, marmalades, syrups, jellies, fruit juices, sauces, pates, vegetables pickled in oil and pickled, sauteed vegetables and meat, legumes and soups, fish, condiments and whatever needs these processes.

It is the ideal system for those looking for a single system to obtain a packaged and ready-to-sell food product from the raw material. Built entirely in stainless steel, it is functional and intuitive; its build quality meets the very high standards that have always been imposed in Frigojollinox. It has been developed to offer small and medium-sized enterprises an all in one system with which to set up an entire laboratory of agri-food preserves.

The BM50 TOP is equipped with two tanks that work totally autonomously and automatically. The Vacuum tank allows you to cook with almost all possible methods and in particular with the cooking/concentration method in vacuum. This method is ideal for the production of high quality jams and marmalades as well as sauces, chutneys, mustards, ready condiments and much more. The product, in fact, cooks at 50°C and in much shorter times, thus avoiding losing the organoleptic characteristics, the flavor, the aroma and the color of the fruit used without having to add gelling agents or sugars. The Stery tank allows you to sterilize food products of any type as long as they are packaged in suitable food containers. It also allows you to steam and cook in water or other liquid up to 135°C.

Automatic vacuum concentration system at low temperature 50-60°C (vacuum pressure less than -901mbar).

Automatic cooking system with variable temperature up to 140°C.

Automatic rotary candying system with dedicated stainless-steel basket with shelves (optional on request).

Automatic cooking system in water or other liquid under pressure or at atmospheric pressure up to 135°C.

Automatic steaming system up to 135°C.

Automatic saturated steam or water sterilization system (HACCP standards) up to 135°C.

Automatic system for pressure compensation so as to avoid accidental opening of the containers during the sterilization phase and allow the use of any material resistant to high temperatures.

Automatic mixing system with variable speed scraping mixer.

Indirect heating system, with gas burner or electric heaters, through a cavity with thermal liquid in order to distribute heat evenly on the bottom and walls of the tank. Equipped with automatic management and high energy efficiency (on VACUUM tank) .

Direct heating system through gas burner or electric heaters with automatic management and high energy efficiency (on STERY tank).

Automatic system for filling water on both tanks.

Automatic system for cooling sterilized cans through high performance flooding.

Automatic electronic valve system to ensure safe operation.

Loading and unloading system through reinforced stainless steel basket.

Automatic control system with 10″ resistive color touch screen graphic display, SIEMENS® PLC and FJ4.0 management software, setting, storage and real-time display of all the parameters relating to the processes, real-time calculation and display of the F0, F100 and F71 values, creation of a time-temperature graph, storage of all sterilization cycles through an integrated data logger, USB interface for downloading graphics and data, ethernet network interface and wi-fi access for remote control via smartphone tablet or PC and remote assistance.

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT