- New

- New

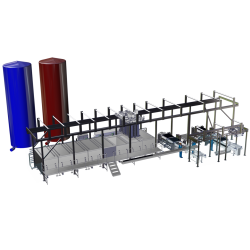

SCREW COOKER

Straightforward, large-capacity steam-heated unit as part of producing high-value meal by cooking a wide range of inputs with fluctuating quality.

Description

INTRODUCTION

Rugged, energy-efficient Haarslev screw cookers are ideal for processing setups where inputs vary in both quality and composition, with a bare minimum of pre-cooking preparation. You can choose throughputs from 2 to 50 metric tons per hour, and the modulating valve for the steam supply makes it easy to process even small volumes if and when needed.

These are straightforward, heavy-duty units in which the steam-heated screw rotor and flights mounted on it distribute heat evenly while the rotor gently moves the material through the cooker. This only involves a minimum of mechanical agitation, which provides better quality outputs, using as little energy as possible.

BENEFITS

- Energy-efficient, with maximum throughput per dollar

- Easy cleaning using standard high-pressure equipment

- Easy inspection of the cooked material at outlet end

- Good basis for more effective solids/liquid separation in downstream presses and decanter centrifuges

APPLICABLE FOR

- Sea or land-based fish meal plants

- Poultry rendering plants

CONTINUOUS FEED OF FRESH FISH OR POULTRY RAW MATERIAL OF VIRTUALLY ANY KIND, ENTERING COLD

- Steam-heated screw rotor moves material through the cooker

- Modulating valve for adjusting steam pressure

- Hinged hatches for easy inspection and cleaning

- Condensate from the jacket discharges through a manifold, with steam traps

- Housing with steam-heated jacket, insulation and stainless steel cover

- Screw rotor fitted with flights on its entire length

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT