- New

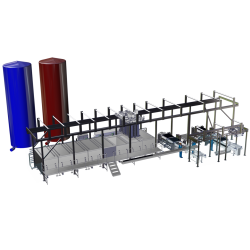

Turbofilm™ Mini

The Turbofilm™ Mini is a continuous cooking system syrups for soft confectionery (pectin, gelatin or blends) or hard candy, toffees and lollipops.

Description

The Turbofilm™ Mini is a continuous cooking system syrups for soft confectionery (pectin, gelatin or blends) or hard candy, toffees and lollipops, designed for use in 50hg/hour ServoFilm™ Mini systems.

Efficient production of gummies, jellies and hard candy

Combining continuous dissolving and cooking into a compact, portable module brings the benefits of high efficiency, low energy use and simplicity of operation.

Suitable for production and lab applications

Ideal for high-value functional and medicated environments; or to produce short runs/large batches for research, product development and test marketing purposes.

Designed for easy installation and maximum efficiency

The compact, skid mounted unit has a small footprint, is easy to install, and all parts are readily accessible for cleaning and maintenance.

The Turbofilm™ Mini comprises a reservoir tank, transfer pump, plate heat exchanger and vacuum evaporation chamber, mounted on a common stainless steel support frame.

150L Reservoir Tank:

- Fed on demand with sugar slurry from an external mixing system

- Stainless steel construction

- Working capacity of 150 liters

- Insulated sides

- Inverter driven stainless steel stirrer

- Self-draining base

- Hinged lid fitted with a safety switch

- International Dairy Federation (IDF) outlet connection

- Configurable call & low level control

Slurry Transfer Pump:

- Designed to pump confectionery slurries for long periods with the minimum of maintenance

- Stainless steel rotors

- Stainless steel pump chamber

- Pressure relief valve

- Packed gland shaft sealing with hardened shafts

- Variable speed drive with manually adjusted inverter

- International Dairy Federation (IDF) connections

- Pumping chamber front plate is quickly removable for maintenance and access

Plate Heat Exchanger:

- Used to dissolve, cook and evaporate moisture

- Stainless steel plates

- Product temperature indicated on HMI

- Cook temperature regulated via a three term control loop

Evaporation Chamber:

- Vacuum is applied to reduce the temperature of the cooked syrup

- Vacuum system contains a direct condenser

- Discharge pump and pipework are steam heated

- A modulating valve controls the vacuum level.

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT