- New

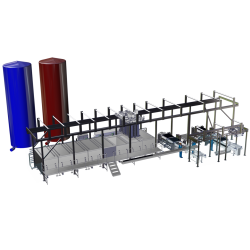

FreeTherm 150

The Gold Peg FreeTherm is a purpose designed batch processing system for a complete range of product types.

Description

Processed cheese, pasta filata types, sauces, purees, baby food, meat, pet food and more. All ingredients are gently mixed by two independently controlled augers. Product heating utilises unique Gold Peg direct steam injectors and the product is de-aerated using an integrated vacuum system. Temperature is accurately monitored by Gold Peg unique self-cleaning temperature probes. After processing, the product is discharged into an insulated buffer tank, with an agitator, to wait for delivery to downstream systems. Great flexibility and different options make the FreeTherm a multifunctional batch processing system for a wide range of products.

Multifunctional

Multifunctional batch processing system for cost effective production and providing excellent finished product quality

Highest flexibility

Mixing pattern flexibility increases blending and heating efficiency

Direct steam injectors

Effective heating using unique direct steam injectors which eliminate product hotspots

Vacuum system

Integrated vacuum system for de-aeration for density control and colour stability

Clean-In-Place

Different automatic programs for easy production and CIP Fully enclosed, CIP able, hygienic design ensuring product safety

Central control surveillance system

Central control and surveillance system for high operator comfort

For additional functions

or different execution

Bin lifter for ingredients addition Level measurement for exact dosage and traceability Steam conditioning unit Powder and ingredient addition systems Shear pump for products like spreadable cheese Shaft seal upgrade Cleaning via connection to an existing CIP system Combined discharge and CIP pump Double jacketing of processing vessel Different mixing auger executions available depending on the product requirement Further options on demand

Machine data

LxWxH: 3,650 x 3,550 x 3,150 mm 400 V, 50 Hz, 3 phase different voltages available

Capacity data

Up to five batches per hour Depending on product and temperature

Heating temperature

Up to 98 °C (208 °F) by direct steam injection

Cleaning

Automatic cleaning via spray balls and integrated systems

Can be connected to an existing CIP system

Execution

All product contact surfaces are 316 L stainless steel

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT