- New

Automatic tilting cooker with mixer

Tilting pans with mixer are cooking the product with continuous stirring and discharging the food into receiving trolleys with the discharge spout always at a constant height from the ground.

Description

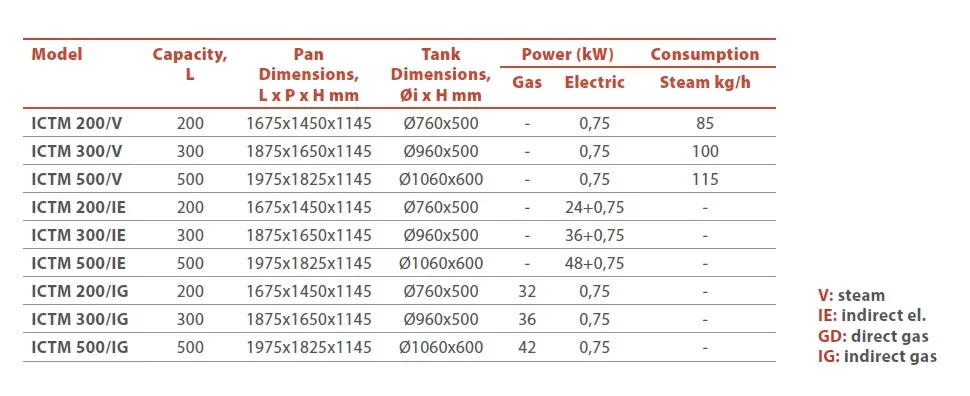

Designed for catering industry, school kitchens, restaurants and food industry. Options: indirect steam boiling, indirect electric, indirect gas. Capacity: 200, 300 or 500l.

Appliance of innovative design, combining the advantages of cooking the product with continuous stirring and discharging the food into receiving trolleys with the discharge spout always at a constant height from the ground.

The mixing blades can be customized to suit the types of product to be processed. The automation of the cooking parameters improves the final quality of the product and considerably reduces the kitchen personnel required.

Cooking tank

Cooking tank with bottom in AISI 316 polished stainless steel and walls in AISI 304 stainless steel

Lid

Balanced lid in AISI 304 stainless steel with heat resistant handle

Tilting of the container

Automatic tilting by electric or hydraulic actuator mechanism and automatic block in case of damage Down and up button.

Electric supply: 400V - 3N - 50Hz

Management with dedicated PLC and serial monitor

Jacket

Jacket with bottom and walls in AISI 304 stainless steel

Mixing System

The pan is provided with a mixer with adjustable speed and possibility to automatic reverse. It is built with radial arms or scraping blades in stainless steel and insert in ceramic teflon.

The mixer can be easly removed for cleaning or maintenance

Support frame and panels

Stainless steel frame

Thermal insulation assured by high density ceramic fibre 64/128

Panels in stainless steel, fine satin finish

HEATING SYSTEM

Indirect Gas versions - with Jacket

Heating by means of stainless steel high efficiency tube burners

Ignition by means of manual piezo-electric lighter and pilot flame

Valve-controlled safety tap with thermocouple

Venting grid

Set of jets for different types of gas

Automatic system to block burners during tilting

Jacket water level control taps max/min with the option of automatic filling

Jacket pressure control by means of springloaded safety relief valve calibrated at 0,5 bar, vacuum valve and pressure gauge.

Possibility to apply the automatic air venting of the jacket

Indirect Electric versions - with Jacket

Heating by means of INCOLOY heating elements with adjustable power regulator

Safety thermostat to prevent overheating and keeping the equipment from operating without water

Jacket water level control taps max/min with the option of automatic filling

Jacket pressure control by working pressure switch and spring-loaded safety relief valve calibrated at 0,5 bar, vacuum valve and pressure gauge

Standard power supply 400V - 3N - 50Hz

Indirect Steam versions - with Jacket

Heating by means of steam (from user’s plant line) with a throttle valve allowing a gradual steam inlet

Jacket pressure control by means of springloaded safety relief valve calibrated at 0,5 bar, vacuum valve and pressure gauge

11 other products in the same category:

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT