- New

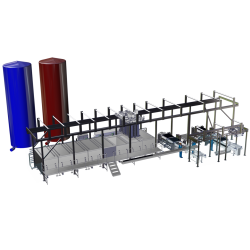

Steam boiling cooker LMS 150, 200

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

Description

Steam boiling catering cooking equipment

Modern technology and high quality materials

These steam boiling pans are manufactured for professional kitchens and also for other food processing factories. Thanks to the use of modern technology and high quality materials our boiling pans fulfil the high utility and sanitary requirements. All our boiling cookers have indirect heating, it means that the main heating tank of the pan consists of a double jacket.

SUITABLE PRODUCTS:

- Thick or thin soups

- Pasta

- Rice

- Sauces

- Various types of boiled food

- Broths

- Dairy-based products

- Coffee

- Boiled vegetables

- Pasteurization of jars (packaged products)

Stainless steel material

All components that may come into contact with food are made of acid resistant stainless-steel of 1.4301 grade and housings are made of stainless-steel of 1.4509 grade.

Condensate drainage collecting at the bottom of the heater

As a standard, boilers are made without safety fittings. They can be equipped with safety fittings, with an adjustable valve for an opening pressure of 0.05MPa. The cooking tank consisting of a double jacket is forming a space called evaporator (heater). Installation of condensate for condensate drainage collecting at the bottom of the heater.

Steam powered devices

Steam boiling pans are steam powered devices for heating and cooking products intended for consumption. The boiler at an operating pressure of 0.05 MPa will open the safety valve and continuous release of water vapor. Safety fittings can be assembled as an additional option, which functions as an additional signaling system.

Optional Accessories:

- Connection hot and cold water: 2 x R 1 / 2 “

- Battery filling hot and cold water

108 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT