- New

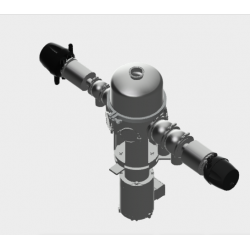

Adjustable industrial mixer AA50

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials).

Description

The AA50 adjustable mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain high dispersion suspensions, emulsions and pastes.

The mixer can be supplied with a variety of low speed or high speed mixers as well as any homogenizing head depending on your product and process. The lifting mechanism can be equipped with pneumatic, electromechanical or hydraulic drive according to customer requirements.

WORKING PRINCIPLE

The operator lifts the stirrer to the required height to position the mobile container. The tank is placed under the stirrer in accordance with the machine axes. The limiters ensure the tank is correctly centered with respect to the stirrer. When the mobile container is correctly positioned, the operator releases the movable part of the device so that the stirrer frame is pressed against the container.

The mixing device is provided with a lid similar to that of a mobile container and when the stirrer is lowered into the container, the lid securely closes the container. In this way, the product is stirred in a sealed container. The stirrer drive is located in the center of the tank.

The AA50 adjustable mixer is an indispensable tool when you need to mix different products without having to clean the mixer after each batch (for example, when mixing colors of different shades). Another advantage is the extremely high level of hygiene, as it is not necessary to pump or transfer the product from the transport container to the mixing container and save a considerable amount of time for each dose.

FEATURES AND OPTIONS

- Designed for any container shape and size

- Any mixer shape or homogenizing head

- Made of stainless steel AISI304 / AISI316L

- Pneumatic, hydraulic or electromechanical drives

- GMP and validation documentation

184 other products in the same category:

- New

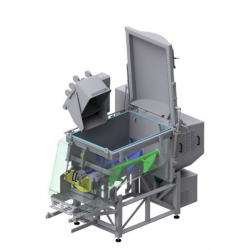

Continuous drum coating machine for adding spices and flavors AD

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT