- New

Mixer

Contract price

Mechanical Dough Developers are for industrial bakers who want to produce high-quality dough in a short time with a small footprint.

UPC:

EAN13:

New product

Description

Mixers

Mechanical Dough Developers are for industrial bakers who want to produce high-quality dough in a short time with a small footprint.

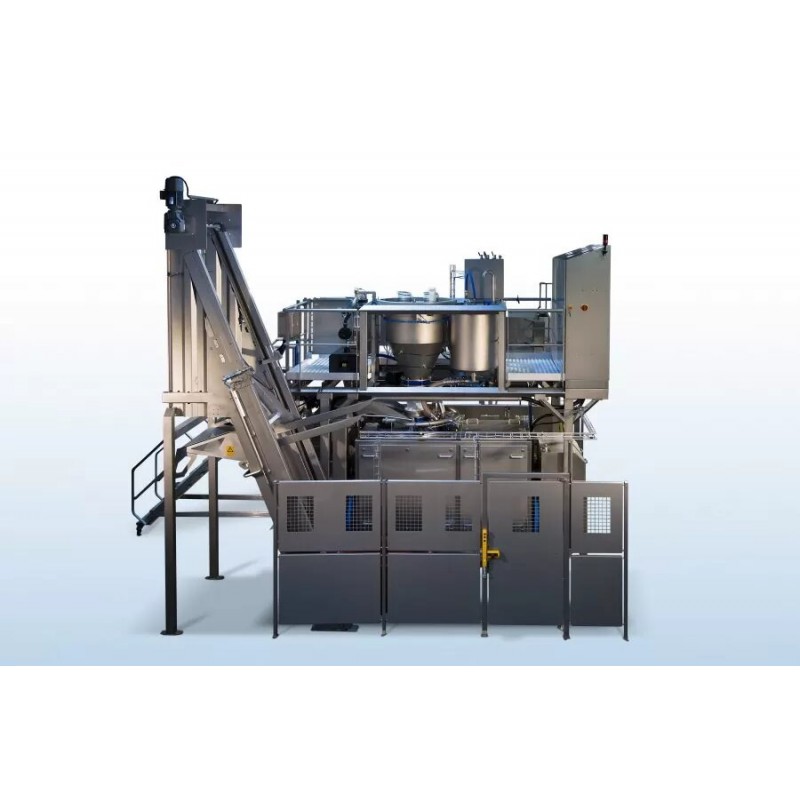

Benier MDD mixers

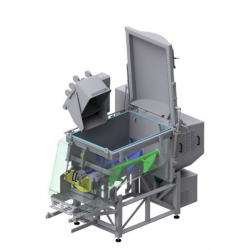

This automated mixing system, including ingredient and dosing system is the next level in dough kneading. Vacuum and pressure cutting allows complete control over the final product structure.

Product information

- For a wide variety of breads, doughs and hydrates.

- High capacity; low end-beginning effect.

- Vacuum and pressure mixing for control over dough and product structure.

- Consistent dough, batch after batch.

- Lower product costs.

- Improved product output.

- Reproducible quantity and quality.

- Lower operating costs.

- High ROI (higher water adsorption).

- Lower labour costs.

- Production is less dependent on the operator.

- Unique design of main bearing seal for quick and easy maintenance.

- Improved hygiene, closed mixing.

- Low noise operation

- Easy to clean (CIP).

Highlights

- Segment: Semi-industrial / Industrial.

- Capacity: from 2,200 to max. 4,620 kg/hour

MDD 100

Specifications

- Flour: 100 kg/batch

- Dough: 185 kg/batch

- Dough output 2.200 kg/hr

MDD 125

Specifications

- Flour: 125 kg/batch

- Dough: 225 kg/batch

- Dough output 2.700 kg/hr

MDD 200

Specifications

- Flour: 200 kg/batch

- Dough: 350 kg/batch

- Dough output 4.200 kg/hr

Can be increased to 225 – 385 – 4.620

184 other products in the same category:

- New

DLM/FS Solid-Liquid Inline Mixer

- New

Blending system Innopro Paramix C

- New

Overturnable Mixer NUOVA VITTORIA

- New

Mincer mixer AK-RAMON PM-32 PM-114

- New

PREMIX FOR WINE AND GRAPE JUICES

- New

Coating and Enrobing machines

Continuous drum coating machine for adding spices and flavors AD

Price

€8,900.00

- New

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

- New

CHOCOCON 150 chocolate / compound processing unit

- New

MIC Turbo – Mixer Granulator – Food

- New

LÖDIGE PLOUGHSHARE® MIXERS (LABORATORY MACHINES)

- New

MIXWORKING BATCH - PASTEURISING PLANTS

- New

Vertical Spindle Dough Mixer 550

- New

Dough-kneader machine МТ-300 K.423

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT