- New

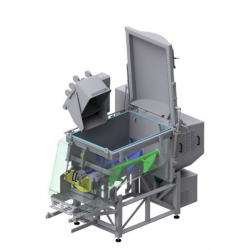

Vitomix ribbon screw mixer

The Vitomix ribbon screw mixer is a mid-shear mixer capable of ultra-short cycle times with up to 8 times more transport volume than conventional ribbon screw mixers.

Description

The Vitomix ribbon screw mixer is a mid-shear mixer capable of ultra-short cycle times with up to 8 times more transport volume than conventional ribbon screw mixers. The Vitomix, also known as ribbon screw blender, also has a wider range of operation using tip speeds from 0.4 m/s to 6.0 m/s.

This multi-functional ribbon screw mixer combines gentle mixing and mid to low shear in the one compact machine. It's ideal for the addition of liquids and creates a homogenous mixture without using lump breakers. The ribbon screw mixer is an energy-efficient mixer that reduces energy costs and saves on mixing time.

HOW IT WORKS

A distinctive factor about the Vitomix is the double ribbon screw which enables a transport capacity of up to eight times that of standard conical screw mixers. The result is a substantial improvement in mixing efficiency and a much more efficient and faster mixing process even at lower speeds.

FEATURES

- Reliable Nauta® mixer technology enhanced for up to 8 times faster mixing

- Combining gentle and mid low shear mixing in one machine

- Addition of liquids creating a homogenous mixture without needing lump breakers

- Coating powders with powders

- Fast mixing of powders, pastes and slurries

- Fast and full discharge with bottom outlet

- Energy-efficient mixing

MODELS

The Vitomix ribbon screw mixer is available in several sizes. A few sizes with their typical characteristics are described below. Please note that these values are indicative only. Detailed information is available on request.

|

Volume |

[m³] |

0.5 |

1 |

2 |

3 |

5 |

7 |

10 |

|

Vessel diameter |

[mm] |

1230 |

1530 |

1900 |

2160 |

2550 |

2850 |

3200 |

|

Vessel height |

[mm] |

1260 |

1690 |

1890 |

2430 |

2870 |

2990 |

3350 |

|

Height incl. motor |

[mm] |

1590 |

2270 |

2480 |

3380 |

3860 |

3990 |

4570 |

|

Typical motor power |

[kW] |

1.1 - 5.5 |

3 - 18.5 |

5.5 - 30 |

7.5 - 45 |

15 - 75 |

22 - 90 |

30 - 110 |

Our expert design and engineering team would happily help you specify the right ancillary equipment to compliment the Nauta® conical screw mixer. These ancillaries may include:

- Outlets

We have various outlet valves to choose from including side outlets, slide gate bottom outlets and ball segment valves.

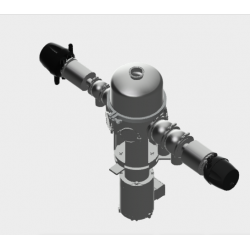

- Liquid spraying system

A liquid spraying system can be fitted with air supported or non-air supported nozzles.

- Semi-domed cover

Eliminate voids with a semi-domed, easy-to-clean cover.

- Sampler

Our new heavy-duty sampler is suitable for handling critical materials with extended life time for seals and exceptional vacuum / overpressure tightness.

- Lump breaker

Special lump breaker for in the product zone with liquid injection (optional) and special sealing in the shaft.

- Access door

Optimal dust and watertight closure on access door using FDA-approved seals.

184 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Continuous drum coating machine for adding spices and flavors AD

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT