- New

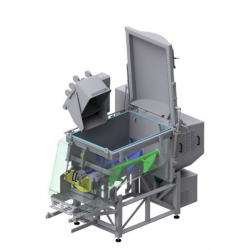

Mixer dryer and Vacuum dryer (VMT)

Very gentle vacuum drying at fast reaction rate for dry, moist and viscous materials at variable filling levels

Description

The spiral mixing blade of the vacuum dryer initiates a three-dimensional flow of the mixing goods; creating a spiral upward movement on the periphery and downward flow in the centre. The mixer dryer is vacuum and pressure tight and heatable by steam, thermal oil or water. Fully temperature controlled: the mixing vessel, the mixing arms, the spiral blade.

The vacuum dryer can be designed for compliance with FDA and 3-A Sanitary Standards to be used as a sterile mixer and reactor which also meets EHEDG requirements.

Further characteristics of the mixer and vacuum dryer

- This jacketed and vacuum rated version is an ideal mixer dryer, vacuum dryer, and reactor.

- Spiral tools, arms and shaft are jacketed and heated.

- This vacuum dryer guarantees quick and gentle drying results.

- It can be used for moist powder, wet suspensions as well as liquids, paste and dough.

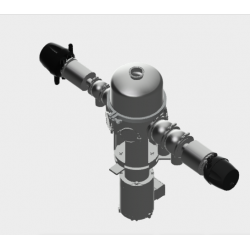

- If the drying process requires deagglomeration, high speed cutting rotors may be installed.

- The mixing device is driven from the top, using only a single top bearing.

- The single-shaft mixer dryer meets all industry standards for surface finish, including sanitary and pharmaceutical requirements, and requires a very small space.

Hot/cold - pressure/vacuum reactions for dry, moist and pasty goods.

The mixer dryer and reactor is suitable for powders, suspensions, pastes and dough (test trials are recommended). Drying is carried out gently but quickly, even if different rheological consistencies occur. The dryer can be used as a sterile apparatus. It meets the requirements of EHEDG and 3-A Sanitary Standards.

Benefits

✓ Particularly fast and gentle drying at low temperatures and low rotational frequencies if, for example, fungal spores, bacterial cultures or effect pigments should be dried.

✓ It is also possible to mix intensively deagglomerating in the same apparatus, at higher peripheral speeds and with several HighShearBlades.

✓ The mixer is optional accessible from the side or from above, it can be cleaned fast, safely and convenient; manually or automatically. On request, it can also be sterilized with steam.

✓ The mixing tool is fully heated and mounted and driven only from above.

✓ The apparatus is highly gastight. A vacuum of 1 mbar abs. is possible.

✓ Particularly large heat exchange surfaces advantage extremely short drying times.

Piloting

amixon® manufactures high precision mixers, vacuum mix-dryers, synthesis reactors and granulators with maximum fabrication depth. All components of the amixon®-mixers are made in Germany. The production of the machines takes place exclusively in the amixon®-factory in Paderborn, Germany. amixon® places special importance on the pilot phase in the test centre. Your mixing processes are simulated here. This way, we support you in your product development phase. amixon® has a main test center in Paderborn (Germany). Further test centers are situated in Japan, Thailand, India and the USA.

184 other products in the same category:

- New

- New

Continuous drum coating machine for adding spices and flavors AD

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT