- New

Dissolver / Syrup production

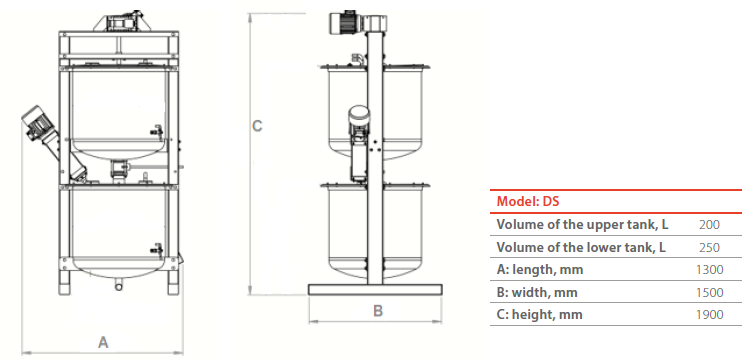

Dissolver constructed for making higher quality marinade, brine with crystal salt, or different syrups with adding flavour enhancers and essences in smaller capacity. Ideally suited for melting pectin, another thickeners, or similar substances.

Description

Suited product:

- marinade

- brine

- dissolved thickeners

- syrup

Dissolver - Design

The plant comprises two operating tanks. The first vessel (top vessel) was constructed for comprehensive dissolvement of crystal salt. The vessel is fitted with a uniquely formed reinforced stirrer, that entirely mirrors the form of the ellipsoidal bottom. A uniquely constructed lower vent ensures no dead (not mixed) zones present while dissolving, together with averting unfinished product discharge. The construction of the machine was made particularly for efficient loading of product, either manually or mechanically. The part of the lid that opens for loading ingredients is as large as possible, and the compactness of the plant (its low height) allows loading ingredients even without a lifter.

The drives of the discharge vents are joined to the central control panel, that enables to open or close the

vents with no need to get to the vessels. Dissolving plant is made from AISI316L grade stainless steel (or another steel grade upon request) with high anticorrosive properties.

How it works

Making of the primary brine is performed in the top vessel. When the essential volume of salt is dissolved, the solution gets poured thanks to the gravity to the lower vessel, where extra additives are therefore added, like flavour or scent ingredients, or others. These ingredients which are prone to evaporating are dissolved with the help of an independent high speed turbine stirrer.

Thanks to this system, it is achievable to acquire higher quality concentrated brine or marinade with uniform distribution of flavor and aroma additives, and maximum preservation of properties. As an option, the equipment may be fitted with a heating jacket (steam or electricity heated), plus it may be put together with no lower vessel.

9 other products in the same category:

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT