- New

Sterilizer

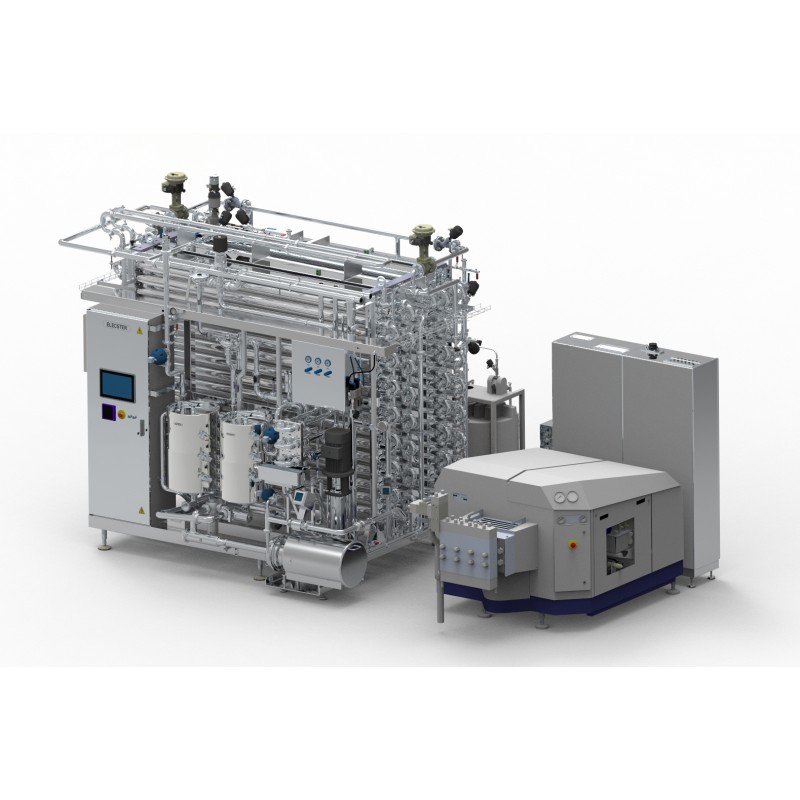

Sterilizer’s construction is stainless steel and complete system includes homogenizer and CIP unit.

Description

Long experience, deep knowledge, high quality components and materials assures the Elecster sterilizer’s high product quality and food safety. Sterilizer’s construction is stainless steel and complete system includes homogenizer and CIP unit.

The capacity and the process temperature of the sterilizer can easily be adjusted to fit different capacities and products. Products like pasteurized milk, powdered milk, flavored milk, low fat cream and drinking yoghurt.

Sterilizer has low utility consumption and the heat regeneration level is approx. 90%. Steam is used as the heating energy source.

Reliable and secure processing

The sterilizing temperature is measured by double detector system and controlled by a two-level low temperature alarm. The alarm system shows the possible operation fault through the monitor. The tubular heat exchangers are protected by a security system which informs about the need of intermediate cleaning. An automatic CIP/AIC system is integrated to the equipment.

Online support and process data storage

The sterilizer is equipped with a remote access control that allows online support. This feature ensures possibility for immediate support and troubleshooting. Sterilizer process data can be stored automatically. Process data can be read with PC or mobile device. Capacieties 2700-10800 L/hour

- Adjustable capacity from 35% to 100%

- Heating by indirect steam

- Tubular multi-tube system

- Complete system incl. Homogenizer & CIP unit

- Homogenizer with automatic speed control

- Easy to operate

- Remote access control

251 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Modular perforated polypropylene shelves for cheese racks / shelves

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

- New

- New

- New

Continuous multi-zone automatic tempering machine TurboNormix 250

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT