- New

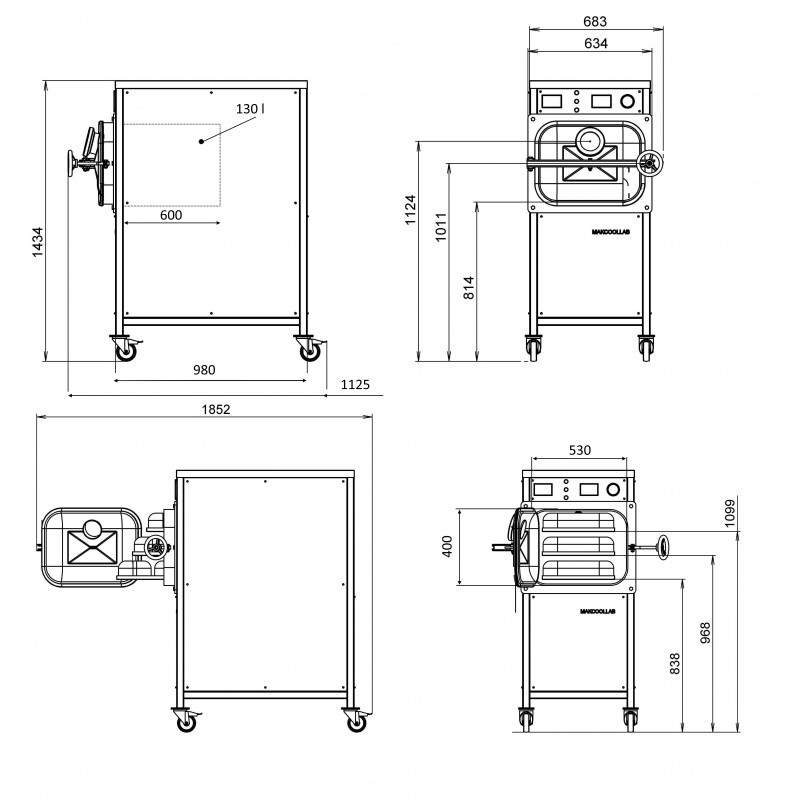

Vacuum cooling lab

This vacuum cooling cabinet model is ideal for small productions, bakeries, allows you to place 3 pallets sized 400x600 mm, or gastro container type GN 1/1.

Description

Advantages of vacuum cooling of bakery products

- Reduced cooling time;

- Shorter baking time, which reduces energy cost and increases productivity;

- Extends the shelf life of the product;

- Gives a more attractive appearance to the product, gives volume, airiness, splendor;

- Requires not too much space.

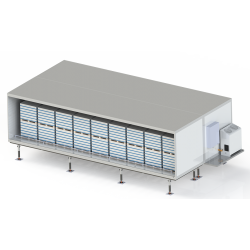

Vacuum cooling is increasingly used in food production. The machine consists from working chamber on a wheel frame with a hatch located in the upper part of the unit, which has a window with illumination and a scraper for cleaning. Tray guides are installed inside the chamber to accommodate standard baking trays or gastro-containers. The machine is equipped with a vacuum pump, condenser, condensate collector and chiller. For proper operation of the unit, before the first start-up, it is necessary to fill the chiller tank with cold water at a temperature of 3-5 degrees Celsius.

The control system includes a temperature controller with a temperature sensor to control the cooling temperature.

Simple and convenient control provides almost automatically all processes, the operator, after loading the product, installs a temperature sensor, sets the temperature, closes the hatch and starts the process.

After reaching the set temperature in the product, the working process automatically stops, the vacuum is released, after the signal, the operator can open the hatch and get the product.

After the operation of the unit, it will be necessary to empty the container for collecting condensate, it is recommended to connect it to the sewerage system.

Operating principle:

Baking of the product continues in a vacuum refrigerator at a pressure below atmospheric, which makes it possible to lower the boiling point of water in the product.

As the vapor evaporates from the product under vacuum, it also cools down. At the same time, the gelatinization process in the product does not stop.

Specifications:

Depth of vacuum, mbar - 20 (17°C)

Chamber volume, l - 130

Tray dimensions, mm - 400x600/ 530x325

73 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT