- New

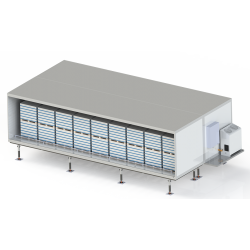

Vertical Model Milk Cooling Tank(Standard)

Milk Cooling Tank

Description

Product Details

Capacity

200 Lt, 300 Lt,500 Lt, 650 Lt, 850 Lt, 1000 Lt, 1250 Lt, 1500 Lt, 2000 Lt

Construction

AISI 304 quality stainless steel

1st wall base is 2 mm and it also has 0,8 mm Ep type laser welded cooler evaporator surface that is coupled to wall.

1 st wall body 1,5 mm

Isolated body 1 mm

Cooler unit and tank body are mounted on single chassis.

There are 1, 25 W 21 d/d redactor and stainless steel mixer blade on redactor.

Isolation range has 50 mm thickness, isolated with water based, non-HCFC high density polyurethane foam material.

Product output has DN50 male sleeve, butterfly valve.

There is also spring cover.

There is Ø 200 mm covered product entry on the cover.

There is manual measuring scale with ‰ 3-4 sensitivity rate.

There are adjustable bolted stands under the tank.

Design that allow zero liquid to remain in the rank during discharge.

Welded sections are welded with 1 st class Argon TIG welding and has 1 st class smooth polishing.

Cooling Group

Fast Cooling without crystallization within minimum milk volume

Minimum gas charging

Cooling with R404 A gas

Peymak Milk Cooling Tanks provide each milking to cool from 35 °C to 4 °C at ambient temperature (32 °C - 38 °C)

Direct Expansion System

TSE 13732/CE/EAC regulation of Compliance certificate

Test of Compliance Certificate

Optionally, design Suitable for 2, 4 and 6 milking time

Electric Group

Protection grade IP 65 Electric control panel

200 Lt, 300 Lt, 500 Lt, 650 Lt, 850 Lt, and 1000 Lt tanks operate at 220 volt energy and 850 Lt and above operate at 380 Volt energy.

Digital thermometer heat level indicator

Electronic control card that is specially designed and is able to control the milk temperature and operation of the tank, easy utilization

Phase protection relay

System disables automatically when the cover of the tank is opened.

Automatic mixing program with special software; Mixer operation time may be adjusted with desired intervals after the milk is brought to desired ser value. (3 minutes of operation, 10 minutes of break)

Washing System

Manual washing

Option

Emergency cooling switch, digital level indicator

Digital weighbridge can be added

|

Capacity |

Min. Milk Level |

Compressor |

Reductor |

Fan |

Total Consumption |

Generator Power |

Class |

|

200 LT |

70 LT |

0,86 KW/0,75 HP Hermetic Kompresör |

0,07 KW |

Ø 300/0,085 KW |

1.02 KW |

2 KW |

2 B II |

|

300 LT |

80 LT |

1,28 KW/1 HP Hermetic Kompresör |

0,07 KW |

Ø 300/0,085 KW |

1,44 KW |

3 KW |

2 B I |

|

500 LT |

90 LT |

1,89 KW/1,5 HP Hermetic Kompresör |

0,07 KW |

Ø 350/0,135 KW |

2,10 KW |

5 KW |

2 B II |

|

650 LT |

90 LT |

1,89 KW/2 HP Hermetic Kompresör |

0,07 KW |

Ø 400x1 Adet 0,18 Kwx2 Adet |

2,10 KW |

5 KW |

2 B II |

|

850 LT |

150 LT |

2,32 KW/2,5 HP Hermetic Kompresör |

0,07 KW |

Ø 450/0,25 KW |

2,64 KW |

6 KW |

2 B II |

|

1000 LT |

150 LT |

2,93 KW/2,5 HP Hermetic Kompresör |

0,07 KW |

Ø 450/0,25 KW |

3,25 KW |

7 KW |

2 B II |

|

1250 LT |

150 LT |

2,5 KW/3 HP Hermetic Kompresör |

0,07 KW |

Ø 350x2 Adet 0,135 Kwx2 Adet |

2,84 KW |

6 KW |

2 B II |

|

1500 LT |

190 LT |

4,95 KW/5 HP Hermetic Kompresör |

0,07 KW |

Ø 400x2 Adet 0,18 Kwx2 Adet |

5,38 KW |

10 KW |

2 B II |

|

2000 LT |

190 LT |

6,3 KW/7 HP Hermetic Kompresör |

0,007 KW |

Ø 450x2 Adet 0,25Kwx2 Adet |

6,87 KW |

14 KW |

2 B II |

|

Capacity |

A (L) |

B (H) |

C (Ø) (W) |

D (H) |

Weight |

|

200 L |

1400 |

1150 |

800 |

1400 |

120 |

|

300 L |

1630 |

1350 |

930 |

1600 |

160 |

|

500 L |

1800 |

1290 |

1075 |

1660 |

175 |

|

650 L |

1800 |

1450 |

1075 |

1750 |

200 |

|

850 L |

2100 |

1300 |

1380 |

1730 |

230 |

|

1000 L |

2100 |

1450 |

1380 |

1900 |

250 |

|

1250 L |

2450 |

1300 |

1690 |

1850 |

320 |

|

1500 L |

2450 |

1450 |

1690 |

2000 |

345 |

|

2000 L |

2700 |

1450 |

1950 |

2020 |

395 |

73 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT