- New

- New

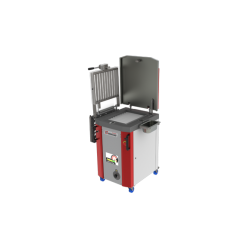

TTCUT

The continuous-action cutting/emulsifying systems

Description

Universal Machine

The fine cutters from the TIPPER TIE TTCut range are great for all-round use, but they also come with special machines for each individual job. The continuous-action cutting/emulsifying systems cover a broad application field in both the food and non-food sectors. There’s a wide range of designs that combine functionality with the latest technology.

Our newly-developed cutting systems provide for super-effective coarse and fine cutting in one or several stages, depending on the product.

That makes short work of cutting and emulsifying fine sausage meat, liver sausage and rind emulsion. Just as easy is producing pastes from fish, fruit and vegetables, as well as sauces or dairy products. You can also use the TTCut for dispersing dry ingredients in liquids or for chopping waffles and broken biscuits.

Cutting System

The non-contact cutting system ensures high, non-varying product quality with defined particle sizes in all emulsions.

The innovative cutting system operates according to the “rotor/stator principle.” This means that uniform, hard-metal cutting plates are fixed on a carrier ring, which acts as the stator. Depending on the cutting ring you choose, you can set a gap of 0.2 to 3.0 mm (special sizes of up to 12 mm available on request).

Inside, a rotor also fitted with cutting edges rotates at a distance of approx. 0.1 mm from the stator blades. Cutting is effective along the entire length of the cutting gap. Simply use different cutting rings to adjust the cutting gap to your requirements. The raw ingredient mix is systematically fed through this cutting system and emerges from the machine homogeneously cut and perfectly emulsified.

Design

An essential design consideration was efficient, hygienic cleaning. The solid, self-supporting stand is very low-vibration and low-noise. Carefully selected materials and advanced engineering give the TTCut a long service life with minimum maintenance requirement.

If you process liquid products, you can attach special opaque tube outlets. The tube systems are simple to attach and easy to clean, and there is the option of additionally fitting a product circuit system to produce emulsions. By feeding the product through in several cycles, the degree of fineness can be increased. Also by successively adding components during circulating operation you can produce sauces, dips or dressings.

Drive & Controls

TIPPER TIE emulsifiers feature proven, robust AC drives in a power range of 11 to 90 kW. State-of-the-art control technology ensures perfect torque control and optimal motor management (from 55 kW, they are equipped with soft starters). All electrical components are wired clearly and accessibly, and installed in the machine in a completely watertight way (IP 65). The user-friendly layout of the controls makes operation simple and intuitive.

Maintenance & Cleaning

The TTCut is exceptionally low-maintenance and service friendly. All the external surfaces are made of stainless steel. Smooth, stainless surfaces, excellent accessibility of all areas, and sloping horizontal surfaces make cleaning fast and hygienic.

The cutting sets lift easily and safely out of the cutting space. The hard-metal blades on the cutting ring are replaceable, so you don’t have to replace the whole ring. That makes a big contribution to low operating costs and high hygiene standards. All TTCut emulsifiers are available in the cutting-set sizes 125/150/180 mm.

Areas of Application & Processes

Meat products: Sausage meat, meat loaf, scalded, cooked and fine liver sausage.

Stable emulsions: vegetable spreads, cold dressings, marinades.

Frozen fruit and vegetables up to 0.2-millimeter pieces.

Cutting left-over bread, reworking biscuits and chocolate.

Nuts, almonds, sesame seeds, spices etc.

Confectionery: reworking chocolate.

Pet food production: cutting, emulsifying.

Laboratory, cosmetics, pharmaceuticals.

Baby food.

181 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT