- New

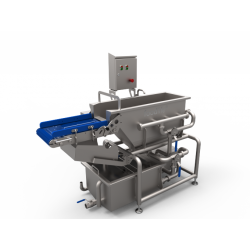

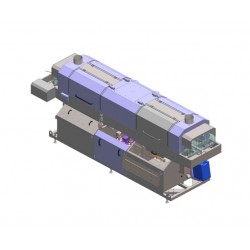

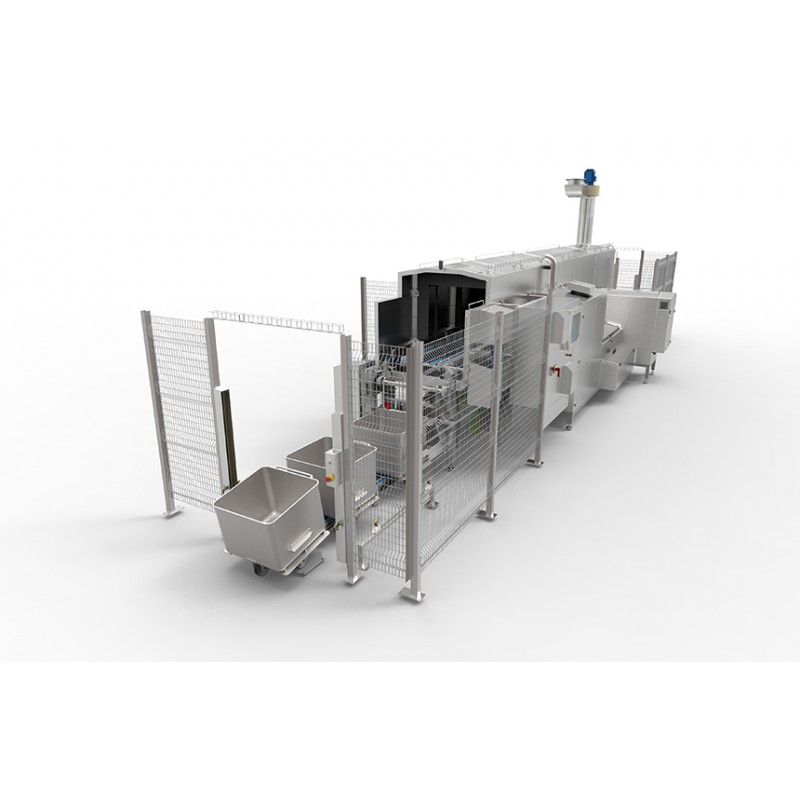

Buggy / meat truck washer TC-2000-CC

Tunnels for the cleaning of buggies and meat truck in continuous process

Description

The continuous cleaning of buggies / meat trucks requires a certain level of experience and knowledge. Firstly, because a very good washing system is needed to assure a good washing result for a buggy running at that speed. But also because the meat truck is a very difficult to manipulate element. Its dimensions, shapes and weight distribution demand a very thought design, and accurate manufacturing and start-up. During the last 10 years, In Mimasa we have had the opportunity to deliver several installations all over the world for automated and continuous buggy handling and washing. So we can affirm that we have already been exposed to all possible combinations of turns, accumulations and loading/unloading positions. The TC series, with TC-2000-CC as its more compact model, draws from this experience and knowledge, bringing already tested solutions to those who are looking for a good management of the automated and continuous 200L and 300L buggies, eurobin cleaning and handling.

Mimasa Technology

Hygienic Design

Retention zones and 90º angles elimination, continuous welding, great accessibility. Let water flow!

Clean ad Aeternum

The best filtering combination of the market, systems that allow safe interventions without stopping the line and solutions for the auto diagnostic.

Born to be Automated

To facilitate the automatization of the sanitizing processes. Washing systems born to be automated.

The 10-Sides

Technology

Ten sides that need to be cleaned. Mimasa does not forget any of them.

Technical Features

Maximum clearance (WxH)

800x800mm

Production

50 u/h

Pump power

18,5 KW

Filtering

Self-cleaning rotary filter

Stages

Wash-Rinse-Disinfection

Heating

Steam or electrical (other options available)

Options and accessories

Adjustable top guiding system for different heights

Lateral guiding for different widths

Steam extractor systems

Detergent and disinfectant dosing systems

Conductivity control

Custom made solution for other elements washing

Recirculated rinse stage before the final rinse

HACCP register and control program

Blow-off between stages

Versiones calorifugadas

118 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

INDUSTRIAL WASHER FOR 200 L BUGGY WITH STANDARD FILTER

- New

- New

- New

- New

Perfectly clean vegetable crates thanks to unique Pivo system

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Industrial washing-machine & forced air drying module

- New

- New

- New

- New

INDUSTRIAL PASS THROUGH WASHER FOR CRATES, UP TO 100 PCS/H

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT