- New

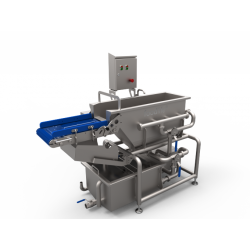

Spiral washer SW

The Sormac SW-50 spiral washer was designed for washing cut vegetables that either float on water or that sink.

Description

The Sormac SW-50 spiral washer was designed for washing cut vegetables that either float on water or that sink. The vegetables are washed intensively in the washbasin and then transported by a vibration chute or outfeed belt where the vegetables are rinsed with clean water.

The washing water is drained to the pump tank through the perforated bottom of the vibration chute. The pump recirculates the water to the washbasin.

The swirling action and force of the water can be regulated separately through manually adjustable valves and nozzles to assure a perfect washing operation and the desired dwell time of the produce. The switch cabinet has pushbuttons to activate and deactivate the flycatcher, pump and vibration chute.

The machine is constructed entirely of stainless steel and some plastic parts. Also the vibration motors are executed in stainless steel.

Product specification

The SW-50 spiral washer is suitable for washing all kinds of cut and uncut vegetables.

Capacity

Up to 1,500 kg/hour (3,300 lbs/hr) (depending on the specific produce and the desired dwell time).

Features

Stainless steel vibrators

These are positioned away from the product flow.

Adjustable water flow

The pump speed, valve position and positionable nozzles enable all (cut) fruit and vegetables to be washed.

Numerous machine versions

Machine can be engineered with numerous options. This allows the machine to be assembled according to customer specifications.

Touchscreen

Easy operation to activate/deactivate all components, set pump speed and read out water temperature.

Options

Outfeed belt

By placing an outfeed belt instead of a vibration chute behind the washer, the product can easily be transported further in the production line, ideal for delicate products.

Flycatcher

The SW-50/350 can be equipped with a flycatcher that removes insects and small particles.

Rotary sieve in the pump tank

The small particles can be collected in a crate by the rotary sieve.

Fan

A fan creates agitation in the wash water and ensures an intensive washing process. It also makes sure the product is submerged.

Cooling coil in the pump tank

This coil cools the water in the pump tank before it is pumped back into the washer.

UV-C-unit

The water is pumped through ultraviolet light, which destroys the bacteria in the water.

Dosing unit for additives

For accurate dosing of additives to the washing water.

Carousel for 3 centrifuge baskets

3 centrifuge baskets can be placed on the carousel quickly and easily. The carousel is equipped with swivel castors so it is easy to move.

Platform for 3 or 6 centrifuge baskets

A solid rack to store 3 or 6 centrifuge baskets.

Castors

To move the machine flexibly through space.

118 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

INDUSTRIAL WASHER FOR 200 L BUGGY WITH STANDARD FILTER

- New

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Industrial washing-machine & forced air drying module

- New

INDUSTRIAL PASS THROUGH WASHER FOR CRATES, UP TO 100 PCS/H

- New

Perfectly clean vegetable crates thanks to unique Pivo system

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT