- New

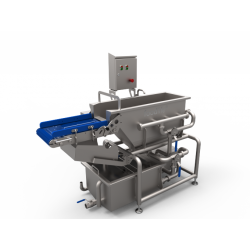

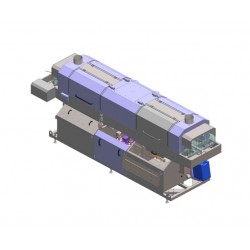

Bucket washers

The bucket washing systems are fully automatic

Description

The bucket washing systems are fully automatic and are equipped with state-of-the-art technology making them the ideal solution for optimizing both production processes and energy consumption. They are suitable for all sectors of the market and comply fully with the Tailor Made concept, the real jewel in the crown of Colussi Ermes.

Possibility of washing buckets of different shapes and type, and of different heights and dimensions.

Hourly washing capacity of up to 500 buckets.

Available in the cabin version with a manual or sliding door, or in the tunnel version with 1-5 tracks.

Bucket washing systems designed to obtain maximum hygiene levels.

The bucket washing systems are equipped with particular high pressure systems, able to remove even the most stubborn residue. They have been designed and certified to eliminate any bacteria, even the most aggressive, according to pharmaceutical/hospital hygiene standards.

TECHNOLOGY

TAILOR-MADE: the machine is designed, developed and configured for each individual customer, on the basis of their requests and requirements.

Structure in stainless steel with thick insulated panels to prevent heat dispersion. This technology offers a dual function: reduction in energy consumption and noise reduction.

Customized washing programs based on the type of material held within the tank.

Washing programs designed to obtain maximum energy efficiency.

High pressure to remove all types of stubborn residue or dirt.

Responsible dosing of chemical solutions to protect the environment as well as the operators involved in the bucket washing operations.

Multiple water heating systems.

Significant savings of energy, water and detergent.

Reduction in maintenance costs and times.

A special mechanical system allows the top part of the system to be raised allowing easy cleaning and maintenance operations as well as full inspection.

Reliability and performance levels unchanged over time.

Constant and uninterrupted monitoring of the functions and critical parameters.

Interfacing with centralised monitoring systems in compliance with HACCP standards.

118 other products in the same category:

- New

- New

- New

Industrial washing-machine & forced air drying module

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

INDUSTRIAL WASHER FOR 200 L BUGGY WITH STANDARD FILTER

- New

- New

- New

- New

- New

- New

Perfectly clean vegetable crates thanks to unique Pivo system

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT