- New

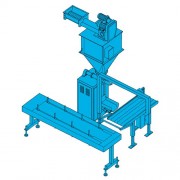

SIMPLE A1

Bagging machines for preformed valve bags, suitable for fine and mixed powders.

Description

Its distinctive rugged construction and minimal maintenance requirements, together with its capability for excellent production performances, have made SIMPLE A1 a global success.

Over 1,700 installations on all 5 continents prove that this is the ideal tool for quick, effective bagging operations.

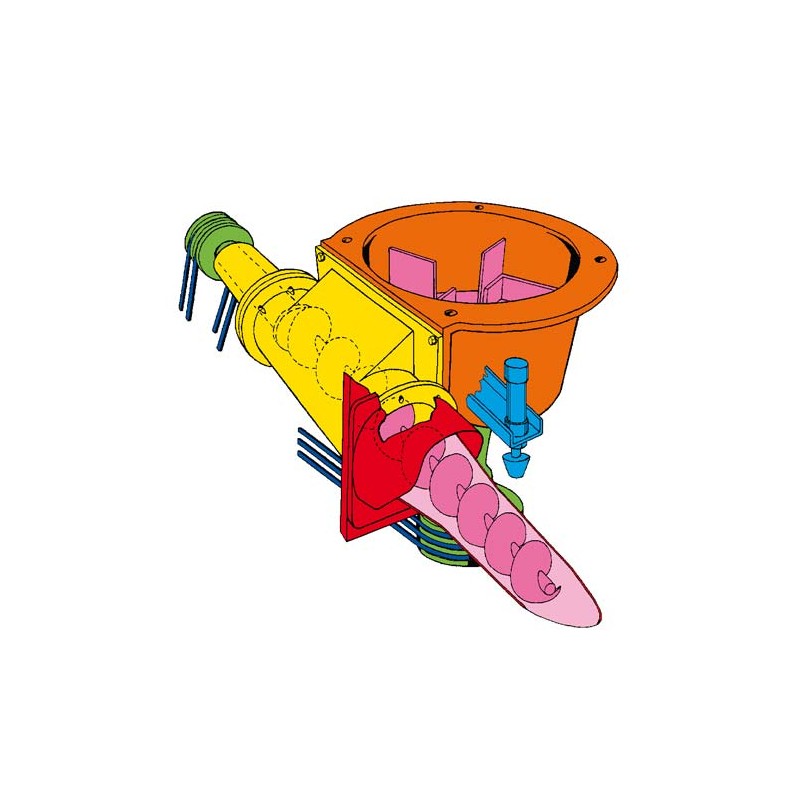

The particular operating principle, derived from a Paglierani patent registered in 1955, involves a vertical turbine that feeds the horizontal bagging auger at a constant rate.

This combined action ensures unbeatable efficiency and minimal dust emissions.

VIBRATING SADDLE

During filling, the bag is supported by a vibrating saddle that compacts the product to reduce the pack size.

The vibration stroke is adjustable.

As an optional, full bags can be ejected automatically via a pneumatically operated swivel movement of the bag saddle.

SYSTEM ENGINEERING

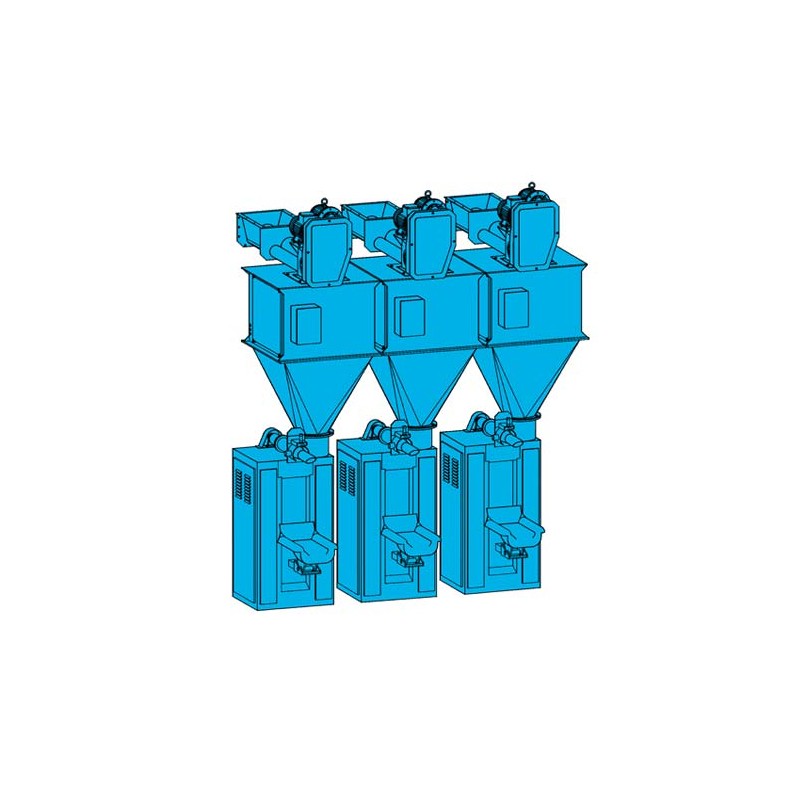

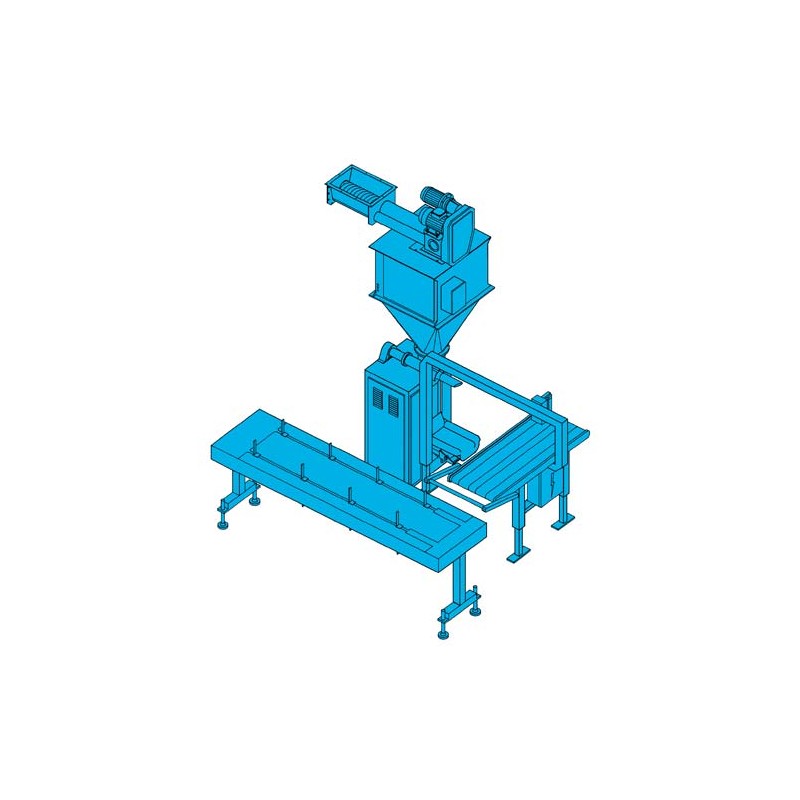

In line with the PAGLIERANI philosophy which aims to design integrated systems for higher production efficiency, SIMPLE A1 bagging machines can be combined with model NE net weight weighing machines.

One or more bagging machines can be installed in-line depending on production requirements (diagram A).

The system is automated through combination with the model FB automatic empty bag feeder (diagram B).

GENERAL SPECIFICATIONS

VALVE SIZES

STANDARD

The SIMPLE series can be equipped with bagging spouts suitable for valves in the standard sizes 110 mm · 130 mm · 150 mm · 180 mm (with the same valve size).

SPECIAL

Spouts for special valve sizes (other than those listed above) are also available on request.

HOURLY PRODUCTION RATE

The production rate depends on valve size, product type and bag weight.

The graph illustrates the relationships between these parameters.

MINIMISATION OF DUST DEPOSIT ZONES

The bagging machine is designed in accordance with the strictest hygiene regulations, minimising the zones where dust deposits may accumulate.

The bagging machine is also completed with a hood for extraction of the dust generated during bagging procedures (extractor fan not included).

TWO-WAY VERSION

Right or left-handed, to facilitate system engineering.

BEARING PROTECTION

With dustproofing device consisting of a compressed air pressurisation circuit.

448 other products in the same category:

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

- New

Heavy Duty Double Chambers Vacuum Packaging Machine J-V012W

- New

- New

- New

- New

- New

- New

- New

- New

MC4TB High-speed wrapper for chocolate tablets and bars

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

LRC-700 Combined Robotic Case Packer & Palletizing System

- New

- New

- New

- New

- New

- New

- New

PP220 Horizontal Type Pre-Pouch Doypack Packaging Machine

- New

Servo Carton Former/Carton Erector/Tray Former/Tray Erector

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Machine for the production of thermoshrinking bags SA-V TVB

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Seamer for soft drinks, beer and carbonated soft drinks

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT