- New

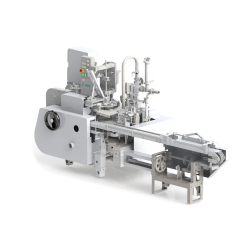

Rotary cup filling and sealing machine

The ROT-O-MIN is designed for the filling of liquid, semi-liquid and dry products like set yoghurt, fruit yoghurt, drained yoghurt, cream cheese, processed cheese, nuts, etc.

Description

The ROT-O-MIN is designed for the filling of liquid, semi-liquid and dry products like set yoghurt, fruit yoghurt, drained yoghurt, cream cheese, processed cheese, nuts, etc.

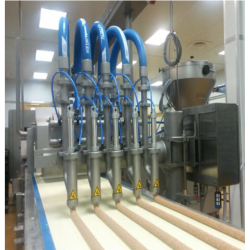

Depending on the capacity desired and the size and shape of the containers. the ROT-O-MIN machines are available in 1 – 6 row editions. Machines operating with stackable cups are provided with automatic cup dispensers. For bottles, jars and unstackable cups, the ROT-O-MIN can be supplied with a star-wheel and in-feed / out-feed conveyors.

All parts in contact with the products, as well as the support frame are made from stainless materials.

A series of optional equipment can be added to the Primodan filling machines depending on the desired hygienic level and which products the machine should handle. By adding features like Pulsed light sterilization of cups, UV-C treatment of lids, MAP (Modified Atmosphere Packaging) solutions and HEPA filters to the machine – the machine enters the ULTRA CLEAN hygienic level and becomes suitable for filling particularly sensitive products.

It is also possible to add INLINE FRUIT MIXING equipment to the machines for mixing in jam or flavor just before the fillers in the filling machine. By adding this equipment, it becomes possible to make fast changeovers between various flavors/jams with very little product waste. It also eliminates the necessity for mixing tanks prior to the filling machine.

The inline mixing system is naturally fully CIP cleanable and, if a CIP plant is not available, we can offer you this equipment – which is also controlled from the filling machine.

Add-on features

The ROT-O-MIN can be delivered with cassettes for cups or a star-wheel for filling cups and jars.

The features that can be added to this machine include a wide range of options e.g. buffers for the cups and snap on lids for 20 minutes´ buffer time, UV-C treatment or Pulsed Light sterilization of cups, UV-C treatment of sealable lids, Primoreels foils on reels solution, HEPA sterile air filter cabinet, compensator for filling of hot products, Vision check for correct placement of foils, twist-on lid station and many other features. A small CIP plant is also available for manual or automatic operation (controlled from the ROT-O-MIN touch screen panel).

Best product Features

Flexible

The ROT-O-MIN is a very flexible machine, where changes between cup heights are activated simply by pushing a button on the control panel.

Hygienic

The ROT-O-MIN is designed to be very hygienic. All surfaces are drainable, the top of the frame is angled and the doors are without frames.

Versatile

Versatility is a keyword for ROT-O-MIN. It is able to run many different formats and the design allows a wide selection of features.

High capacity

The ROT-O-MIN is available from 1-6 rows with capacities up to 14,000 cups/hour

220 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

- New

- New

- New

- New

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

- New

- New

- New

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

- New

- New

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

- New

- New

- New

- New

- New

DABL series automatic aseptic plastic bottle filling and capping machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

- New

- New

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT