- New

- New

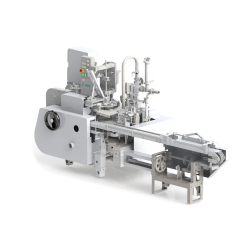

Blow Molding Machine CPX

YSXZB Series automatic rotary preformed cup filling and sealing machine is applicable to pack the products like yogurt ,milk,mineral water, beverage , ice cream, seasoning and so on.

Description

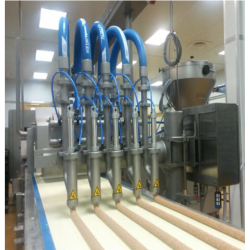

YSXZB Series automatic rotary preformed cup filling and sealing machine is applicable to pack the products like yogurt ,milk,mineral water, beverage , ice cream, seasoning and so on.The process is from cup separating, sup falling,quantitive filling, suck cap film,sealing,and product conveying.The choice of the machine model and number of filling heads depends on the factors like required output, size and type of packaging and requirements for additional equipment.

The machine can provide a lot of solutions for the below field:suitable for both traditional and innovative packaging designs, quick change-over to alternative packaging, different ways of container closing.

Applicable Filling material:Liquid:yogurt ,milk,mineral water, beverage , ice cream, seasoning and so on Cap film material:Al+plastic laminated film;paper+plastic laminated film. Pre-cut lid or film roll. Preformed cup type: Paper cup,Plastic cup,Alu.cup etc.

| Main Technical Data: | |||||

|

Function name |

Brand | Brand country | Function name | Brand | Brand country |

|

Main motor |

SEW | German | Operation center |

SIEM ENS |

German |

|

High pressure combination valve |

Eugen Seitz | Switzerland | Low voltage electrical appliance |

Schneider / SIEM ENS |

France /German |

|

Stretch cylinder |

Rexroth | German |

Infrared heating tube |

PHILIPS | Netherlands |

|

Linear Guides |

Rexroth | German | Infrared thermometer | OPTEX | Japan |

|

Gas source filter |

FESTO | German | Encoder | SICK | German |

|

Torque clutch |

MAYR | German |

Limit switch |

OMRON | Japan |

|

Low pressure control solenoid valve |

MAC | USA | Photoelectric switch | SICK | German |

| Frequency converter | Schneider | France | Proximity switch | SICK | German |

| PLC | SIEMENS | German | Intermediate relay | OMRON | Japan |

|

Program mable Controllers |

SIEMENS | German | |||

Main parameter:

| PRODUCTION DATA | Mould cavities |

N | 16 | |

| Max. body diameter |

mm | 75 | ||

| Max. Height | mm | 260 | ||

| M. diameter | mm | 38 | ||

| Max. preform Height |

mm | 140 | ||

| Max. capacity | ml | 750 | ||

| Nominal output for 500ml, bottle(*) |

pcs/h | 32000 | ||

| DIMENSIO NS | Host | Length *Width)* Height |

mm | 3800X2400X3200 |

| Weight | kg | 21000 | ||

| Heating furnace | Length) *Width)* Height |

mm | 5800X1400X2200 | |

| Weight | kg | 2500 | ||

| ELECTRICAL FEEDING |

Voltage | V | 380 | |

| Frequency | Hz | 50 | ||

| Total power installed |

kW | 260 | ||

| Main motor power installed |

kW < | 5.5 < | ||

| Medium power absorbed(**) |

kW | 80-100 | ||

COOLING /HEATING SYSTEM |

BASE MOULD | Water inlet | ℃ | 10~20 |

| Water inlet pressure |

bar | 5 | ||

| Flow | m3/h | 10 | ||

| BODY MOULD | Water inlet temperature(**) |

℃ | 10~20 | |

| water inlet pressure |

bar | 5 | ||

| Flow | m3/h | 18 | ||

| Heating furnace But water |

Cooling water temperature(**) | pressure | 10~20 | |

| Water inlet pressure | bar | 5 | ||

| Flow | m3/h | 8 | ||

| SERVICE AIR | Nominal pressure |

bar | High pressure to low pressure | |

| Air rate (**) | m3/min | |||

| Filtering grade (filter) |

micron | |||

| Humidity | ||||

| BLOW AIR

|

Nominal pressure |

bar | 40 | |

| Air rate (**) | m3/min | 20 | ||

| Filtering grade(filter) |

micron | 0.01μ | ||

| Maximum pressure dew point |

℃ | +3℃ | ||

| Oil | Maximum concentration 0.01 mg/ m3 | |||

| HEATING | Heating groups * pcs |

n | 16*6 | |

| ENVIRONMENT | Environment temperature (**) |

℃ | (20℃-35℃)±3℃ | |

| Environment humidity ( without condensate) |

% | ≤70% | ||

| Max. altitude (over sea) |

m | |||

| CONNECTIONS | Connection service air |

Inch. | 1 | |

| Connection blow air |

Inch. | 2 | ||

| Connection water and oil |

Inch. | 2 | ||

Main technique:

|

1) Hopper and feeding mechanism: computer monitoring, no need for assistance; according to different types of preforms, the output speed can be adjusted arbitrarily |

|

|

2) Heating furnace: When heating, the preform rotates while moving forward in the furnace to make the wall of the preform heat evenly; specially designed rapid hair cooling device; specially designed defective preform detection and ejection device |

|

|

3) Blowing part: full monitoring by the host computer during the entire blowing production process |

|

|

4) Special formwork system: The mold base is equipped with a pressure balance device to minimize the mold clamping line of the bottle during the molding of the bottle, ensuring the quality and performance of the bottle. |

|

|

5) Stretching secondary blowing system: secondary blowing system, pre-blowing, high-pressure forming blowing, secondary blowing pressure, time adjustable . |

|

|

6) Manipulator device: Made of stainless steel, precision machining; rotary manipulator with torsion overload protection to prevent equipment damage when equipment is not damaged |

|

|

7) Safe and reliable mechanical transmission: using variable frequency motor, gearbox and inverter of SEW Company of Germanyod grade requirements. |

|

|

8) Mold: audited by professional designers |

|

| Description: | 1. Actual production depends on preform shape, preform wall thickness, bottle design and section quality |

| 2. Change according to different generation conditions, pressure and other factors | |

| 3. The above water, electricity and gas parameters are calculated on the basis of 500ml water bottle. | |

220 other products in the same category:

- New

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

- New

- New

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

DABL series automatic aseptic plastic bottle filling and capping machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT