- New

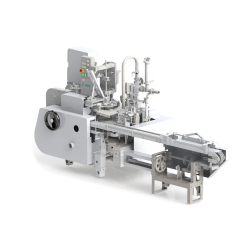

Automatic can filler INTEGRA 606 + 608

With the automatic can filler INTEGRA® 606 + 608 you increase the filling output even further.

Description

The two machines stand for high-performance filling also in the prepackaging area. Model 606 works with 3 double cycle stations, model 608 optionally with 4 double cycle stations.

The equipment is operated via a central touch panel with integrated scale display. Here you can centrally set all container and filling parameters and monitor the equipment control system.

Your benefits – Automatic can filler INTEGRA® 606 + 608

Calibrated high speed filling even for finished packages

The filler is operated via touch panel with integrated weigh scale terminal

All container and filling parameters can centrally be set and the operation of the filler can be monitored

255 product data records can be stored

Cyclic monitoring of the filling unit, e.g. mis-alignment protection, tare and tolerance checks, monitoring of product flow and fill time

Integrated push-bar conveyor transporting the cans in double cycled operation exactly below the working stations

Communication and data exchange with customer’s supervisory system optional

ATEX compliant

220 other products in the same category:

- New

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

- New

- New

- New

- New

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

DABL series automatic aseptic plastic bottle filling and capping machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

- New

- New

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT