- New

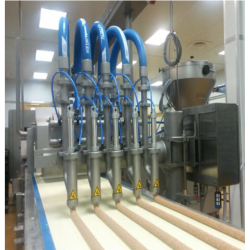

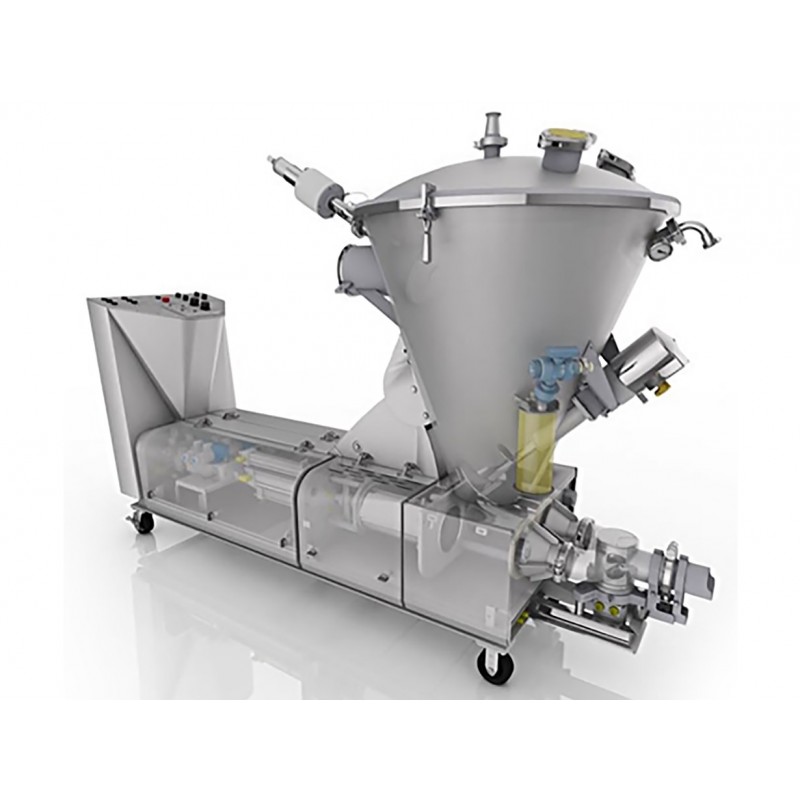

Opti 100 Vacuum Stuffer & Pump

Contract price

Features a twin-piston vacuum stuffing and pumping system with a variety of hopper options designed to match product requirements.

Reference:

Opti 100 Vacuum Stuffer & Pump

UPC:

EAN13:

Description

Maximum capacity 10,000 lbs per hour, 250 psi pumping pressure. Ideal for smaller application design. Can be equipped with an optional hydraulic fluid cooling unit without the need for water cooling.

Features:

- Simplicity; no digital controls

- All the basics of a twin piston Marlen pump at a fraction of the cost

- Small footprint and easily portable. Low profile design accommodates space constraints and heavy-duty casters provide smooth unit mobility

- 10,000 lbs pumping capacity with a maximum of 250 psi pumping pressure

- Marlen’s unique high-differential vacuum ensures maximum removal of entrapped air resulting in denser product, more accurate portion control, and longer shelf life

- Patented, hydraulically-driven front valve delivers positive shifting for continuous, even product flow, and more accurate portion weight control

- Twin-piston pumping system designed to gently deliver products to downstream processes. The zero-slip design maintains product integrity for products ranging from the highly abrasive to whole muscle. The system is gentle on your products and reduces wear on the unit, extending its life.

- Hopper options include standard open top hopper to full vacuumizer hoppers with augers for load assist for complete versatility

- Designed for easy operation & control

- Externally-adjustable diffuser valve (Patented)

- Push-button controls

- Proven twin-piston design

- Largest product openings

- Zero-slip design eliminates product degradation

- Minimal product damage and fewer cuts

- Designed to reduce the need for downstream accumulators or bypass

- Precise metered flow or constant pressure control

- Built to USDA accepted standards

- Smaller number of parts simplifies cleanup

220 other products in the same category:

- New

Washers, Cleaners & cip systems

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

Contract price

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

Manual honey filling unit 0NRG.38

- New

Pressure overflow bottle filler - model GI 3300

- New

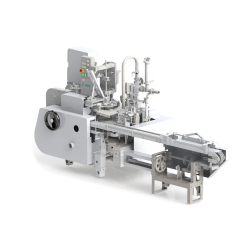

ARU - PROCESSED CHEESE FILLING AND WRAPPING MACHINE

- New

FME 50 (Rotary Form-, Fill- and Seal Machine)

- New

In-Line-Filler SERVOFI LL F100

- New

Bagging and filling machine – VBA

- New

Automatic can filler INTEGRA 606 + 608

- New

Packaging & Sealing equipment

TPM 1000 fully automatic thermoforming packaging machine

Contract price

TPM 1000 fully automatic thermoforming packaging machine

- New

Semiautomatic filling machines

- New

CONTINUOUS VACUUM FILLER F9

- New

Automatic groups piston-filler seamer

- New

Filling & Stuffing machines

DABL series automatic aseptic plastic bottle filling and capping machine

Contract price

- New

Automatic groups vacuum fillers-seamer

- New

Filling & Stuffing machines

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

Contract price

- New

Hydraulic Filling Machine DF 250 X

- New

MINI form, fill and seal machine

- New

Vertical form fill sealing

- New

- New

- New

Filling & Stuffing machines

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

Price

€3,459.00

- New

Ice Cream Filling Machine BG-2

- New

PET filler Innofill PET NV

- New

ARM-B2/B3 - BUTTER FILLING AND WRAPPING MACHINE

- New

ORG - BULK BUTTER FILLING MACHINE

- New

Jam Filling Machine DUPLEX 150

- New

Filling & Stuffing machines

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

Contract price

- New

Filling & Stuffing machines

GF series automatic plastic bottle filling and capping production line

Contract price

- New

Spoon Honey Filling And Capping Machine

- New

Ketchup Filling, Capping and Labeling Machine

- New

AR2T - CURD FILLING AND WRAPPING MACHINE

- New

Hydraulic sausage fillers VINS/22

- New

Bagging and filling machine – VLRB

- New

Casing filling machine SR 90N

- New

ECOFILL HT2 Semi-automatic filling machine

- New

SP-10 JUSPER Introduction

- New

FSL 48 Form, fill and seal lines

- New

ICEPACK - Rotary Filling Machines

- New

Piston bottle filler - model PI3300

- New

FS 37 Form, fill and seal lines

- New

Can filling station ELEMENTRA 14

- New

Bottle Filler Innofill Glass Micro DPG

- New

RFS 120 - CUP / TUB FILLING MACHINE

- New

Filling & Stuffing machines

Vertical form-fill and seal machine of the “Economy” series

Contract price

- New

Bottle reject model 1900-002

- New

FC-25 Sausage Fillers / Stuffers

- New

ICEPACK - Linear Filling Machines

- New

EMF - MULTIPLE WRAPPING MACHINE

- New

Piston filler 2-100 ml P 100

- New

ARG - ICE CREAM FILLING AND WRAPPING MACHINE

- New

RFS 40 - TUB / CUP FILLING MACHINE

- New

Filling & Stuffing machines

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

Contract price

Highly corrosive product rotary pressure overflow filler

- New

ARM - BUTTER FILLING AND WRAPPING MACHINE

- New

Filling & Stuffing machines

Filling and seaming groups for aluminium and tin plate cans

Contract price

- New

Cheese - Volumetric Filling

- New

FL-D.L.M. linear mass flow dosing machine

- New

Automatic can filler INTEGRA 64

- New

Coffee Capsule Filling And Sealing Machine

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT