- New

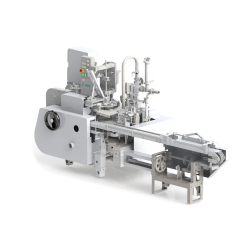

Filling-capping machine for flexible pouches TEF

Semi-automatic dosing machine, designed for filling and capping different spouted pouches.

Description

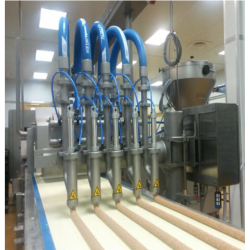

The machine is air driven and applicable for filling and capping flexible pouches (those that have an already existing spout) with liquid / semi liquid products by mean of a volumetric piston filler with a 50 -1300 ml dosing range and closing the same with 1 size of plastic screw cap.

All the parts in contact with the product are manufactured with AISI 316 L stainless steel and food grade gaskets. The cap is tightened by a pneumatic motor with torque regulation.

Technical features

The main frame of the machine is made out stainless steel AISI 304, and is on wheels. All parts of the equipment including the shaft, that gets in contact with the product are manufactured using stainless steel AISI 304. The machine has a pouch manual positioning.

- Air consumption in about 250 Nl/min.

- Requirements: air compressed 2÷6 bar.

Filling unit consists of:

- Volumetric dosing unit from 50 to 1300 ml, AISI 316 L stainless

- Food grade set of gaskets

- Three way rotary valve

- Pneumatic two way no drop valve with switch off nozzle

- Food grade flexible hose

- Hose tail that connects the unit to the storage tank

Single head capping unit consists of:

- Pneumatic motor

- Stainless steel chuck for one size of plastic screw cap

- Manual control for adjusting the height of the equipment

- Nitrogen injection unit

HOW IT WORKS

The employee that operates the machine places the pouch on the collar. By using a hand-wheel control, the filler regulates the capacity of product. Speed of filling and suction can be adjusted. When the lever is manually moved, the filling valve starts working; with a press of a button, the employee then begins the filling process. Towards the end of the filling process, the machine injects nitrogen in the pouch empty space to expand and preserve the product shelf life, which effectively helps conservation of the product. The nitrogen injection time and flow can be adjusted using the pressure regulator. Eventually, the employee places the cap on the spout, puts the closing head in capping position, through the lever mechanism. The cap tightening is managed.

OPTIONALS

- S/steel collar for holding another spout size and shape

- S/steel custom made chuck for 1 size of plastic screw cap

- Surcharge for 200-5000 ml filling range (instead of 50-1300

- 15 liters AISI 316 conical hopper

- 30 liters AISI 316 conical hopper

220 other products in the same category:

- New

- New

- New

- New

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

- New

- New

- New

- New

- New

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

- New

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

- New

- New

- New

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

- New

Vertical form-fill and seal machine of the “Economy” series

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT