- New

Automatic can filler INTEGRA 64

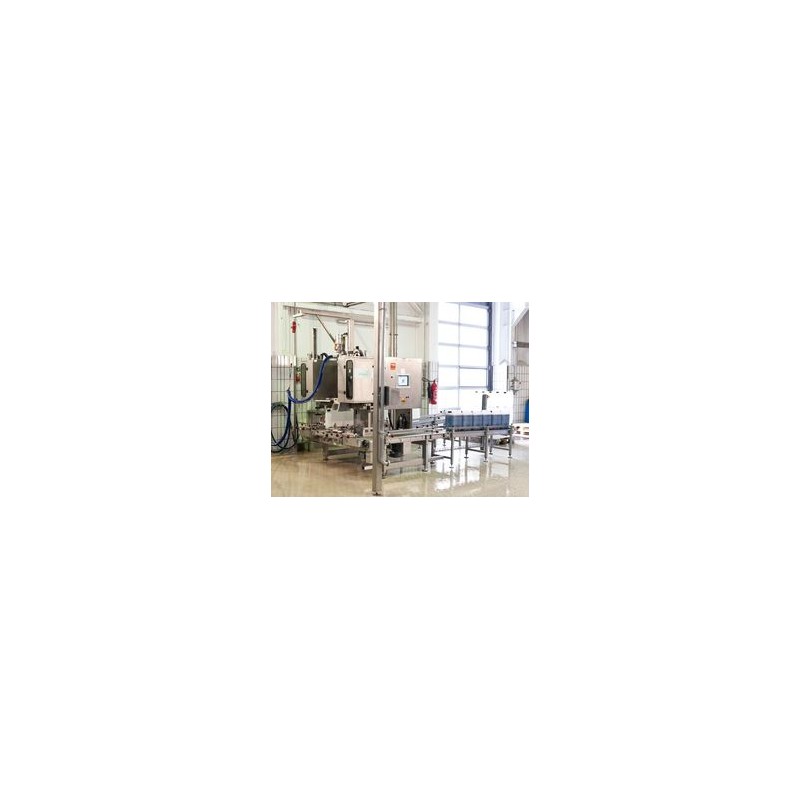

If you want to use a compact, highly integrated automatic filling unit, then the automatic can filler INTEGRA® 64 is the right choice for you

Description

If you want to use a compact, highly integrated and high-performance automatic filling unit with a small footprint, then the automatic can filler INTEGRA® 64 is the right choice for you. The conveyor system is preferably assembled in U-shape to enable an ergonomic operation by one operator. Starting at one location, empty cans and caps or push-in plugs are fed, while the closed cans that have been filled with calibrated accuracy are subsequently palletised.

To increase the output, you can supplement the automatic filling unit at any time with a can station, cap or plug sorting pot or by a palletising aid or palletising robot.

Your benefits – automatic can filler INTEGRA® 64

Very cost-effective solution as the whole control and operating modules are directly at the filling machine

Sturdy base construction with levelling feet

Simple installation

Simple operation with touch panel and integrated weigh scale display

255 filling parameters for different products can be generated

Control of customer’s product pump or pilot valve is included

Standard design with 2 weighing ranges

Standard Single-Point load cell made of stainless steel

No checkweigher required for finished packages

Appropriate product hose available

Also available in stainless steel design

Easily upgradable for higher output or automation degree

2nd filling place can either be used with pre- and final filling to increase the output or as an alternative, be operated for quicker batch or product change

220 other products in the same category:

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Pneumatic piston filling dispenser for liquids 300 - 2500 ml

- New

- New

PSM-06 - Stick and Tetrahedron Pack Powder Filling Machine

- New

- New

- New

Filling and seaming groups for aluminium and tin plate cans

- New

TPM 1000 fully automatic thermoforming packaging machine

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

GF series automatic plastic bottle filling and capping production line

- New

- New

- New

- New

LQ-RCGF Washing-filling-capping 3 In 1 Machine For Juice

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

- New

Highly corrosive product rotary pressure overflow filler model RF48-18-BL

- New

Vertical form-fill and seal machine of the “Economy” series

- New

- New

- New

DABL series automatic aseptic plastic bottle filling and capping machine

- New

- New

- New

- New

- New

- New

Canfillmatic TESTAROSSA Filling lines for carbonated liquids

- New

- New

- New

- New

- New

English

English

Deutsch

Deutsch

Français

Français

Español

Español

Italiano

Italiano

Português PT

Português PT